Vibracoustic has developed an all-new overrunning damper isolator pulley as the company attempts to reduce fuel consumption and emissions by up to 1%. The solution for efficient auxiliary integration in a drivebelt prevents sagging to significantly improve efficiency.

While the performance of downsized engine units has improved, maximum harmonization of the ensuing forces and vibrations on start-up of the engine presents a constructional challenge.

During the very first second of engine start-up, huge forces need to be controlled at near-idle speeds. In addition to affecting comfort, these disharmonies also cause high stress on the auxiliaries in the belt drive.

Designed with an additional one-way clutch function for the three-cylinder engine. The one-way clutch is closed during regular driving operation. However, in the case of crankshaft rotation delay, the one-way clutch opens, enables motion, and prevents auxiliary “re-turning”.

The V-ribbed belt consequently remains adequately tensioned in each load state, even in the case of low pre-tension. The one-way clutch function enables the forces impacting on the belt on start-up of the engine to be significantly reduced.

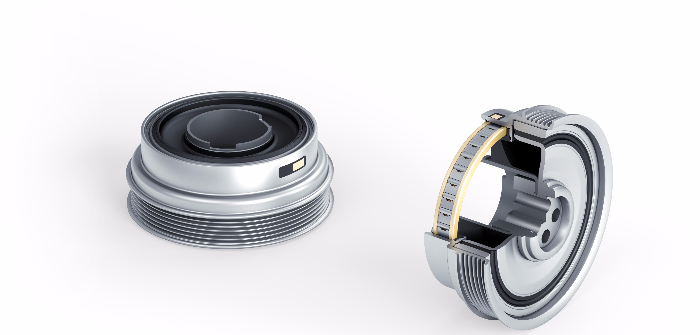

The core components of the design include a metallic hub which is connected to the front of the crankshaft and accepts the flux of force. An elastomer spring enables the isolation function.

A metallic outer ring is enclosed, serving as the inner running surface of the one-way clutch. Two cage structures ensure the secure one-way clutch positioning. The outer ring of the one-way clutch then provides the connection to the pulley, through which the V-ribbed belt for the auxiliary drive runs.