Vitesco Technologies and Continental’s Powertrain division have won a contract to supply electric heating elements for diesel catalytic converters to a major European vehicle manufacturer.

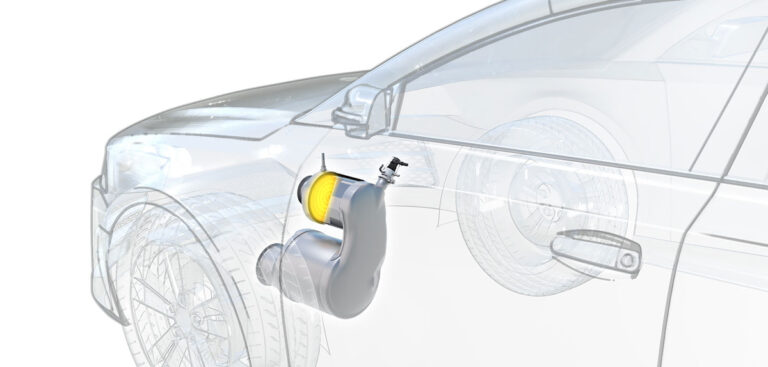

The technology, named the Emicat e-catalyst, will be used in two of the manufacturer’s 48V hybrid van models and has the capability to rapidly heat up the catalytic converter at any time, increasing the efficiency of exhaust-gas aftertreatment.

During testing, a mild hybrid demonstration vehicle fitted with a diesel engine and Emicat, demonstrated how the 4kW heating output could drop both NOx emissions by 40%, and CO2 emissions by 3%. An ultra-slow test was also conducted where NOx emissions fell by 62%. In this test vehicle the efficiency of exhaust gas aftertreatment rose to 97%.

Klaus Hau, head of the sensing and actuation business unit at Vitesco Technologies, said, “The electrification of the drivetrain, which goes along with higher electrical power, clearly supports emission reducing innovations like EMICAT. The e-catalyst allows a robust emission control with regard to all real driving situations for an extremely clean future mobility.

“Emicat eliminates a decisive weak spot with regard to real driving emissions, namely excessively cold exhaust gases. The first serial production of e-catalysts worldwide confirms the importance of emissions safety in all driving situations.”

Production of the e-catalyst is scheduled to start at the end 2022.