Silicon carbide-based semiconductors are the near-future solution for high-power density, high-efficiency power electronics in EVs, offering far greater temperature resistance and faster switching speed than traditional silicon-based systems. They already see extensive use in motorsport applications and in heavy-duty EV powertrains, but to date, the high cost of SiC-based electronics has proved a hurdle to their widespread adoption.

In a move to rectify this situation, the powertrain business area of Continental, Vitesco Technologies, and ROHM Semiconductor, a specialist in SiC power semiconductors, have signed a development partnership, beginning June 2020.

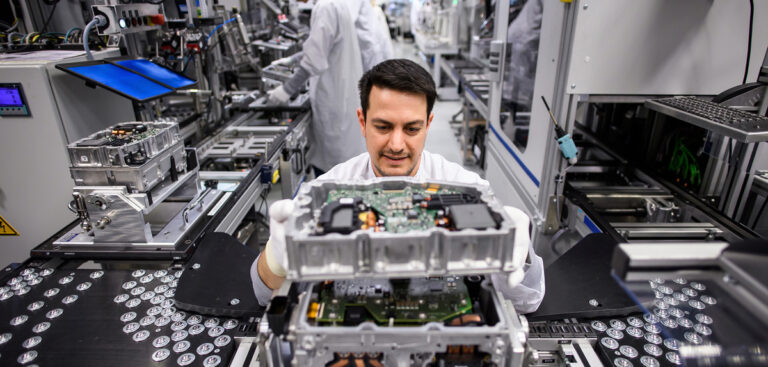

Vitesco Technologies said it will use SiC components to further increase the efficiency of its power electronics for electric vehicles (EV). “Energy efficiency is of paramount importance in an electric vehicle. As the traction battery is the only source of energy in the vehicle, any losses caused by power conversion need to be minimized. We are therefore developing a SiC option within our modular power electronics system,” said Thomas Stierle, executive vice president of the Electrification Technology business unit at Vitesco Technologies.

Vitesco Technologies said it is already developing and testing SiC technology in an 800V inverter concept to confirm the efficiency potential of the technology. It’s approach is to look at the complete system of inverter and motor to identify the best combination of technology and switching strategy.

In this context it said SiC semiconductors – for example, SiC MOSFETs for 800V battery systems – offer more efficient switching in the inverter (higher frequency, steeper switching slopes) and cause fewer harmonic losses in the electric motor. Also, Continental sees SiC technology as a key enabler for super-fast charging technology that uses 800V.

“The SiC option is a very promising future part of our modular power electronics system comprising software, power output stage, and switching strategy,” said Dr Gerd Rösel, head of innovation in the electrification technology business unit at Vitesco Technologies.

“We will work with ROHM on an 800V SiC inverter solution as well as on a 400V SiC inverter solution.” The company plans to start of production of the first SiC inverter in 2025, when the demand for SiC solutions is expected to rise significantly.

It is interesting that Vitesco is considering SiC for both high and lower voltage systems. While SiC is undoubtedly the leading technology for devices running above 600V, there is considerable industry interest in the adoption of gallium nitride-based (GaN) devices, another wide band gap material.

Currently, GaN components are limited to around 650V, as they are fabricated on silicon wafers, but they can operate at even higher switching frequencies and with greater efficiency than SiC.

There is also much work underway to develop buffer materials between the GaN devices and their silicon mountings, to increase their viable operating voltage. However, GaN devices are also more expensive (than SiC), thanks to being produced via metal-organic chemical vapor deposition, a costly and time-consuming process.