Semiconductor specialist STMicroelectronics says it is introducing its third generation of silicon-carbide (SiC) MOSFETs for EV applications. The company claims to have incorporated new know-how to open up even more of SiC’s energy-saving potential. It notes that with the acceleration of the EV market, many car makers and automotive suppliers are now embracing 800V drive systems to achieve faster charging and help reduce EV weight. To this end, STMicroelectronics’ latest SiC devices are specifically optimized for these high-end automotive applications, including EV traction inverters, onboard chargers, DC-DC converters and e-climate compressors.

“We continue to drive this exciting technology forward with innovations at both the device and package levels. As a fully integrated SiC products manufacturer, we are able to deliver continued improved performance to our customers,” said Edoardo Merli, Power Transistor Macro-Division general manager and group vice president of STMicroelectronics’ Automotive and Discrete Group. “We are investing relentlessly to support our automotive and industrial programs expected to generate US$1bn in SiC revenue in 2024.”

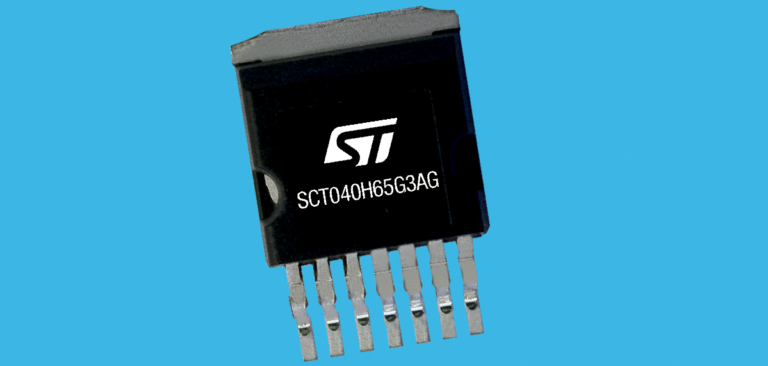

ST has completed qualification of the third-generation SiC technology platform and expects to move most of the derivative products to commercial maturity by the end of 2021. Devices with nominal voltage ratings from 650V and 750V up to 1,200V will be available, giving more choices for designers to address applications operating from ordinary AC-line voltages up to those of high-voltage EV batteries and chargers. The first products available are the 650V SCT040H65G3AG, a 650V unit in a H2PAK-7 package, and a 750V device in die form (datasheet and quotation upon request).

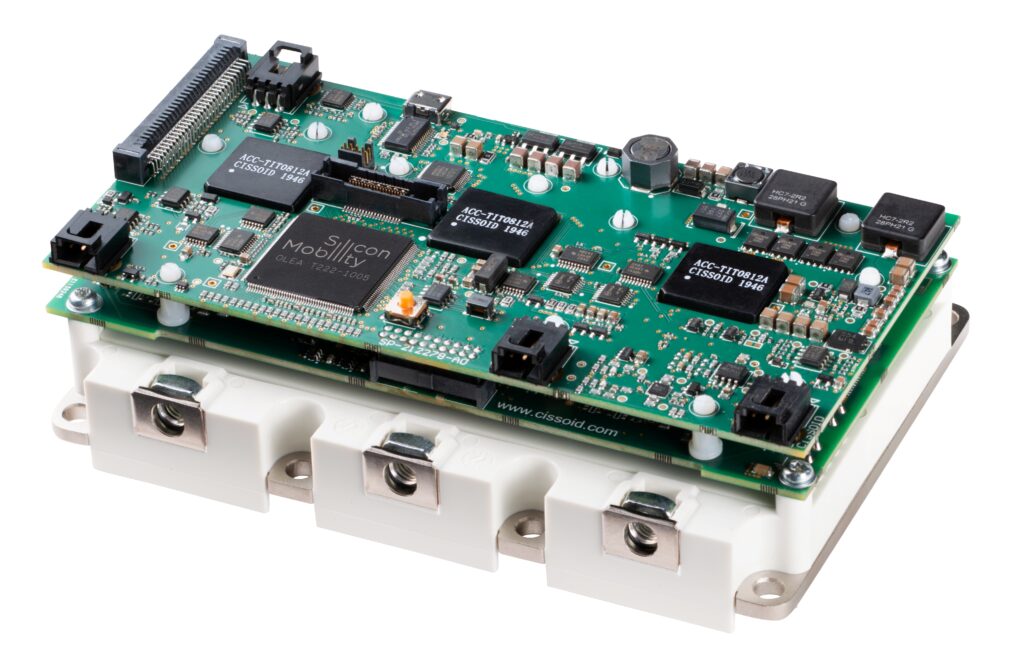

Elsewhere in the realm of SiC-based traction inverter development, Cissoid, a France-based manufacturer of power modules, says it has integrated Silicon Mobility’s Olea FPCU controller with its SiC-based Intelligent Power Module (IPM) platform.

It is claimed that the joint project will deliver a SiC inverter modular platform offering highly integrated hardware and optimized software. This will include a power module and its gate driver with protections and fault management, an ultra-fast FPCU controller and application software optimized for e-motor control.

Cissoid’s IPMs integrate a three-phase 1,200V/340A-550A SiC MOSFET power module with a temperature-robust gate driver enabling low switching losses and high power density. This complements the Olea FPCU controller and Olea APP Inverter software, enabling fast and efficient electric motor control.

“Silicon Mobility ultra-fast Olea FPCU is the perfect technology to control our SiC IPM platform in motor drive applications,” said Pierre Delatte, CTO of Cissoid. “The capability of SiC power modules to switch faster and to operate at higher frequencies makes it essential to have access to a controller technology capable of running real-time algorithms faster. Olea FPCU’s low power consumption is also a key advantage in building highly compact and efficient traction inverters.”