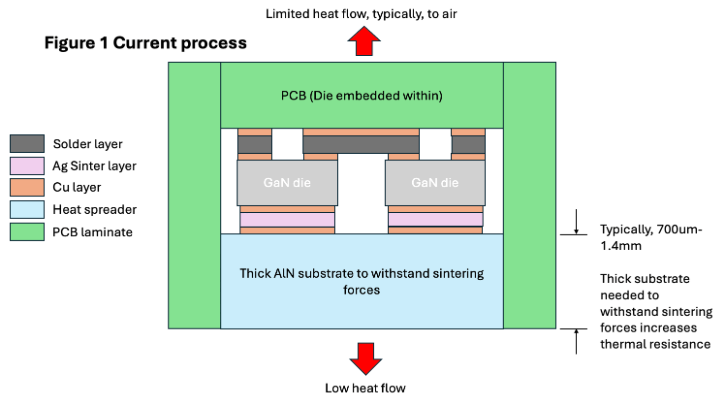

Cleantech company QPT has filed a new patent for attaching dies to heat spreaders or substrates. The assembly process improves heat conductivity and increases reliability as less stress is placed on the substrates – one of the biggest challenges of the semiconductor packaging industry.

QPT developed the new qAttach process for use with the gallium nitride (GaN) transistors it uses in electric motor control designs to enable them to handle the huge amounts of waste heat. GaN transistors are rated for high voltages, but the die size is relatively small for high-voltage transistors. This means there is less surface area from which to remove heat. As a result, they are often downrated to enable them to function without overheating.

qAttach solves this problem as more heat can be removed from the die, preventing it from overheating. This enables GaN to be efficiently used for next-generation, high-power, high-voltage applications in automotive and industrial motors.

Rob Gwynne, QPT’s CTO, said, “We use reliable, well-established technologies from other fields in a novel way to enable us to create the qAttach attachment layer that is potentially down to a fraction of a micron thick. This major reduction in the thermal barrier thickness means that our solution is up to ten times better at transferring waste heat away from the chip. As we refine the process, we are expecting even better thermal transmission rates through this layer.”

QPT claims the qAttach layer is ultrathin, allowing heat to be transferred through and away much quicker to increase the rate of heat removal by up to 15x. The technology has other improvements over the current sintering process. First, the substrate can be thinner, thereby reducing thermal resistance to further assist heat transfer to the heat sink.

Second, the lower pressure required for this process reduces the manufacturing stresses on the dies. This in turn reduces the possibility of device failure – critical for automotive companies where reliability is important.

Last, the ultrathin qAttach layer is not a laminar sheet. Laminar sheets can result in the structure ripping itself apart when heated. This delamination is the largest cause of failures in power packages and QPT says the new approach improves the reliability of the assembled device.