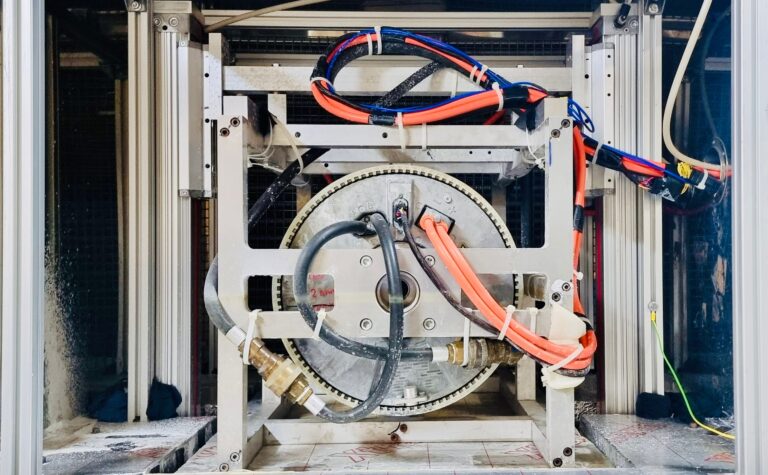

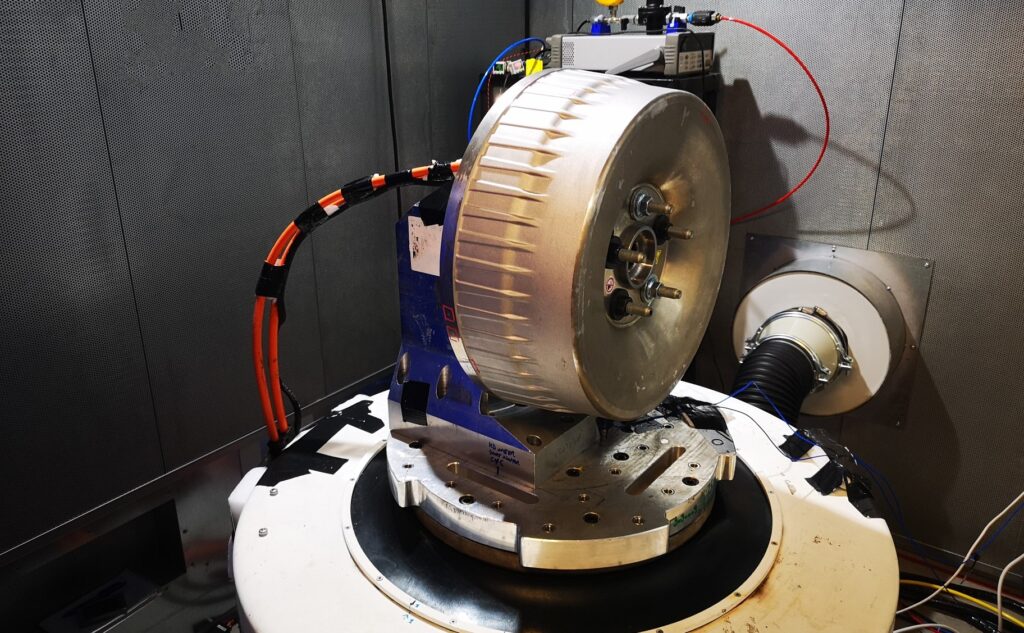

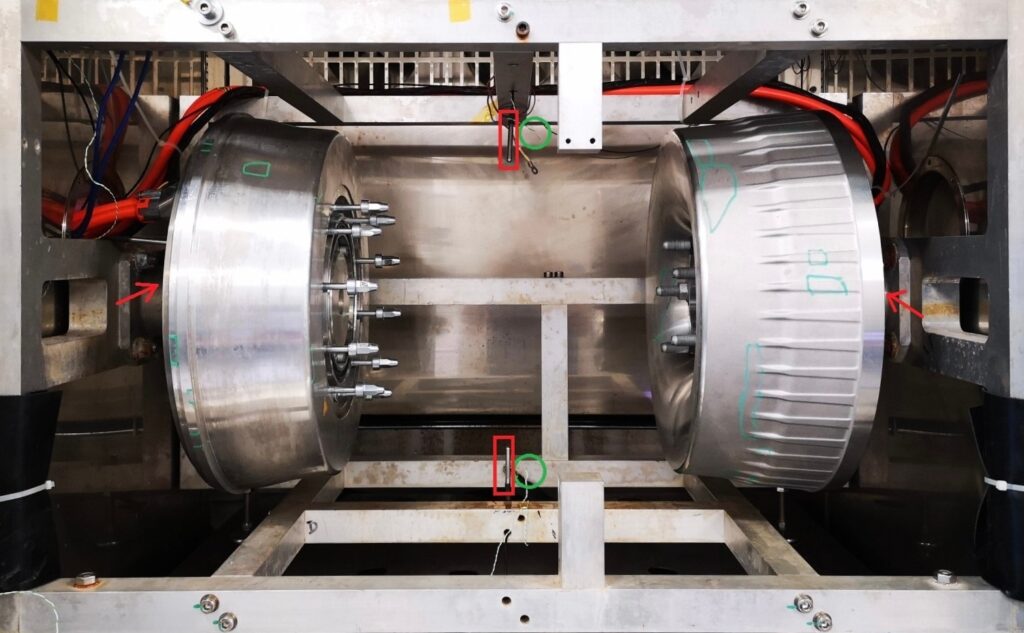

The validation program for the Pd18 Gen5 involved extensive testing, with more than 80 IWMs undergoing 64 test programs to ensure compliance with all relevant legislation, regulations and original equipment manufacturer standards. The IWM is designed for mainstream automotive applications, meeting durability requirements of 15 years and 300,000km. It has also been validated for various environmental conditions, including wading and pothole impact, and meets the ISO 26262 standard as a Safety Element Out of Context, addressing ASIL D hazards – a first for an IWM.

The Pd18 Gen5 IWM is produced at Protean’s IATF 16949-certified facility in Tianjin, China, marking the start of full-scale industrialization of the technology. The company currently provides 400V DC versions of the IWM, with plans to introduce 800V DC versions by the end of 2024.

Stephen Lambert, CTO of Protean Electric, commented, “In-wheel motors are proving to be a pivotal enabling technology for the next generation of EVs. However, much like the first EVs, there needs to be a testing and validation rulebook set out.

“As an industry, much has been discussed about the design and validation challenges of in-wheel motors, particularly the demands of reliability and durability due to the harshest installation environments. Looking to the future, our team has invested heavily in our test and validation procedures to ensure that the Gen 5 IWM, exposed to severe shock, vibration, thermal cycle, sand, dust, water and chemical contamination, is designed to last and do the distance, securing a net-zero future across multiple vehicles and transport solutions.”

Protean will showcase the Gen 5 Pd18 at the upcoming Cenex Expo 2024 at UTAC Millbrook, UK, September 4 and 5.