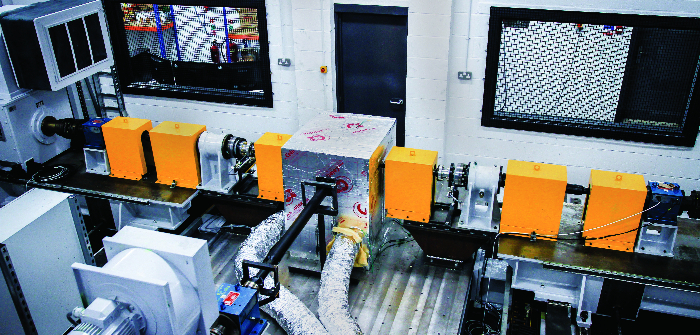

In a major expansion of its test capabilities, transmission and driveline engineering specialist Drive System Design (DSD) is commissioning three new cells, bringing the total on site to ten. The largest cell has five electrical machines, the four output motors each capable of 7000Nm and 700kW, and can handle 4WD HEV transmissions and drivelines ranging in size from passenger cars to trucks and off-highway vehicles. The addition makes this the largest independent transmission and driveline test facility in the UK.

“Demand for this type of work is increasing rapidly with a growing emphasis on CO2 reduction driving up hybrid sales and leading to closer scrutiny of driveline efficiency,” explained Rob Oliver, Drive System Design chief engineer. “The new development, now the largest in the UK, enables us to test a complete range of transmissions, drivelines and vehicles with higher power outputs. We can allow for variations in track width by adjusting propshaft length, and e-machines are able to slide on their beds to accept wheelbase differences.”

Three additional new cells each equipped with three e-machines will complement existing facilities which are in heavy demand. The new cells required significant site infrastructure investment, including a dedicated 11kV, 2MW power supply.

To maximise the value of the new facility, DSD has developed in-house techniques to overcome the traditional challenge of determining driveline efficiency, according to Oliver. “As the torque capacity increases, the differences we are looking for become a smaller proportion of the maximum figure. To improve measurement accuracy, we have developed our own techniques for the calibration of torque transducers which helps overcome this,” he said.

DSD has also created a new, larger hydraulics clean area that allows hydraulics systems to be combined with their electronics to be tested before assembly in the transmission.

The recent expansion complements DSD’s existing engineering capabilities, with a growing team of experienced engineers who are on hand to provide expert interpretation of test data. Decades of combined gearbox and driveline experience, coupled with leading edge simulation and CAE capabilities, enable the consultancy to resolve problems and analyse failures quickly.

The five e-machine rig is already in operation on its first client program for a major European vehicle manufacturer. The new three e-machine cells will come on line later in 2017. To support the growth in workload, DSD is recruiting additional engineers in a variety of disciplines, including three new test engineers.