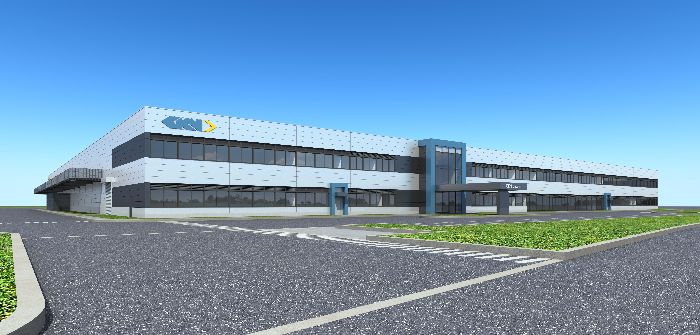

GKN has announced plans to build an all-new driveline production facility in Tokoname, Japan.

Developed as demand for AWD and eDrive systems continues to increase, the plant, which will replace the current Nagoya site, will feature advanced technologies in preparation for growing vehicle electrification in Asia.

With the ability to produce high-quality, next-generation AWD systems and RDMs featuring technologies such as electronic disconnect capability and torque vectoring, the Tokoname site represents a significant technological upgrade.

The project, which will begin in September and is penciled for completion in June 2018, will enable the company to prepare for an expected increase in business over the next four years.

With the company already producing the Multi-Mode eTransmission for the Mitsubishi Outlander PHEV, the growing demand for eDrive systems has resulted in GKN investing in the development.

Phil Swash, GKN CEO, said, “This new state-of-the-art facility will allow us to meet increasing demand for advanced AWD and eDrive systems, while retaining all the benefits of an automotive manufacturing site in the Nagoya area.” By remaining in the Nagoya area, the GKN facility will remain in close proximity to potential new OEMs and provide prospects for future growth.