Horse, a provider of low-emission powertrain systems, has unveiled the digital, automated Matrix Flow production process. The new process has made its debut at the Aveiro plant in Portugal, which produces electric powertrains. It is a fully digital process that replaces traditional conveyor belt systems with autonomous platforms and workstations.

The Matrix Flow system uses mobile programmable cobots (MPCs), developed in partnership with Prolynk (a project by OSE Group) to deliver precise components and sub-assemblies to factory staff and robots. With up to 30 smaller MPCs acting as mobile workstations and components kitting, employees have access to the right parts and tools at the right time, reducing downtime and increasing flexibility.

Managed by a fleet controller hub, the MPCs communicate wirelessly and can adapt to changes in production needs.

Horse says the system has helped achieve efficiency improvements, reducing the factory floor’s physical footprint by 25% and overall building size by 30%. Energy consumption at the site has been reduced by 50%, and paper labels are no longer required, the company says.

Investments in staff training, including virtual reality technology, have been implemented to keep employees up to date with the production process.

Antonio Vaz, chief process engineering officer at Horse, said, “Our new Matrix Flow Assembly line at Aveiro is a hugely significant moment for Horse.

“By delivering unrivalled flexibility and efficiency, this fully digital production method allows us to be agile and responsive while continuing to deliver the highest quality products and meet our commitments to sustainable mobility.”

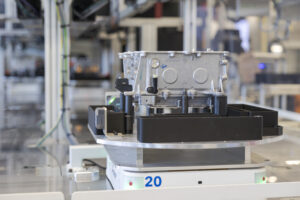

Horse says its is one of the first companies to tailor the process for automotive powertrain production, using it to construct the power electronic box (PEB) that manages the electric motors in hybrid electric vehicles (HEV) and plug-in hybrid electric vehicles (PHEV).

Production of PEB at the plant will start in the coming days, with an initial target of 150,000 units a year, rising to 200,000 by the end of 2024.