Mahle Powertrain is to add a second test chamber to its Real Driving Emissions (RDE) Centre in Northampton, UK.

The £5.1m (US$6.9m) investment in the testing center will be part-funded by a £1.5m (US$2m) grant from the South East Midlands Local Enterprise Partnership (SEMLEP). Demand for the RDE’s facilities has grown exponentially since it opened in 2018.

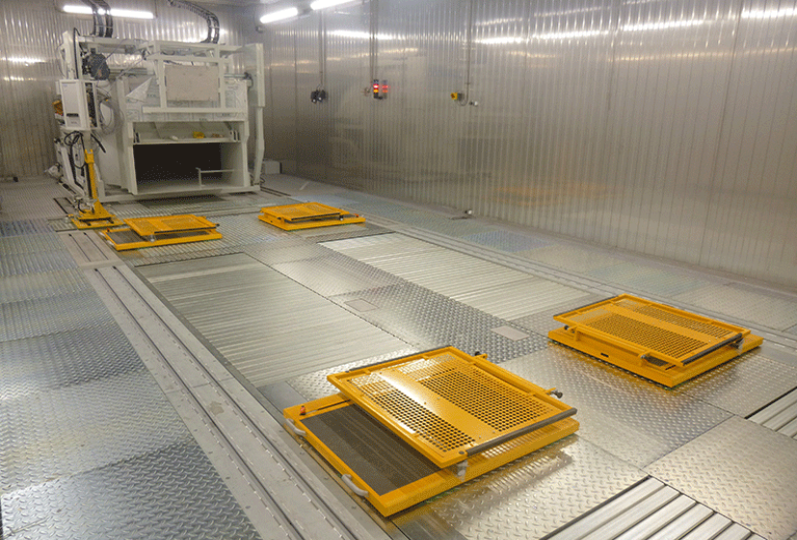

The new test chamber will support the development and validation of EV performance under a range of test conditions and feature a four-wheel-drive dyno and battery emulator, with safety implemented to allow the testing of hydrogen-powered vehicles.

David Pates, head of engineering at Mahle, commented, “This next phase of our ongoing investment program at the RDE Centre will provide vital extra facilities for our vehicle manufacturer and Tier 1 customers. Since the original opening in July 2018, our hypobaric and climatic test chamber has been in virtually constant use. This was even the case during lockdown conditions last year, when we helped manufacturers to sign off whole vehicle test programs despite Covid-19 travel restrictions. While avoiding costly delays at the time, it also points the way to a reliable, faster and more cost-effective way to undertake such programs post-pandemic.”

Mahle estimates that in 2035, 73% of passenger cars globally will still use an ICE as part of their propulsion system, and that by 2040, this will still be over 50%. The company states that due to this, demand for test chambers will still be high as manufacturers focus on hybrid propulsion.

“Given that statistic, it therefore made perfect sense to have a second chamber with a battery emulator, suitable for EV development,” continued Pates. “This second chamber will have an operational temperature range of -20°C to +40°C with the ability to simulate solar loading. For hydrogen-fueled vehicle development we are building in safety measures such as blast walls and a domed chamber roof for stray H2 gas collection. We plan for the new chamber to be ready for customers by the end of Q1 2022.”

“Given that statistic, it therefore made perfect sense to have a second chamber with a battery emulator, suitable for EV development,” continued Pates. “This second chamber will have an operational temperature range of -20°C to +40°C with the ability to simulate solar loading. For hydrogen-fueled vehicle development we are building in safety measures such as blast walls and a domed chamber roof for stray H2 gas collection. We plan for the new chamber to be ready for customers by the end of Q1 2022.”

Alongside the UK investment, Mahle has also made subsequent investments internationally, including the installation of a new powertrain dyno at its US facility in Michigan, and a new e-axle test facility in Fellbach, Germany.

“Our heritage is founded on ICE development, dating back to the first Cosworth road car engines, and since those times we have some notable landmark engines to our credit. However, back in 2008 we could see the way the future of the automotive industry was developing and have been keenly focused on our dual propulsion strategy of ICE and electrification for over a decade now,” concluded Pates.

“There has never been a more technically challenging time in auto powertrain development and our aim is, as always, to help our customers develop the most effective powertrain possible within their budget and timescale. In that respect at least, nothing’s changed.”

After investing in battery cell test facilities last year, Mahle has announced it plans to build a significant battery pack testing facility due for completion later in 2021.