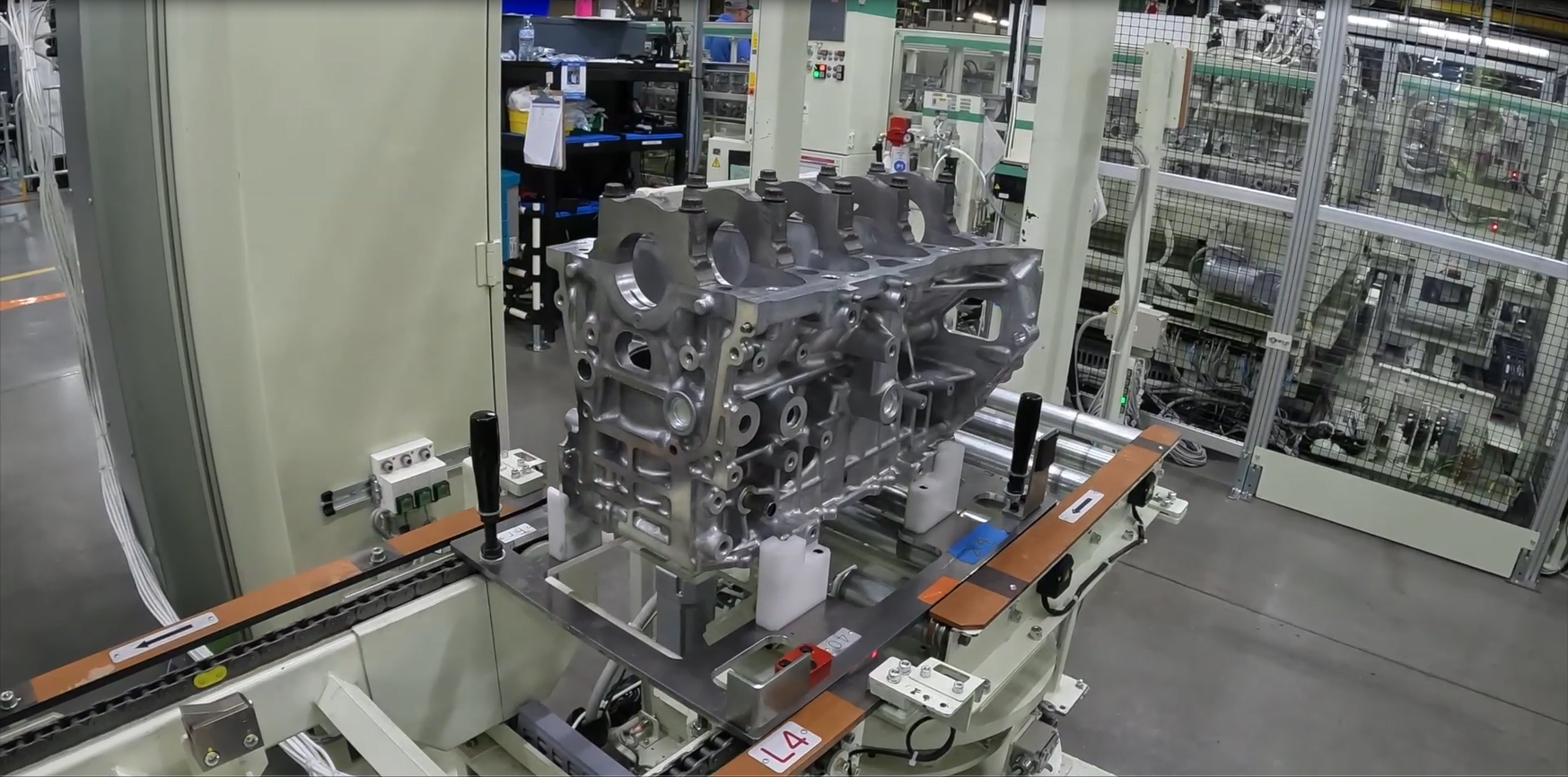

A U$145m flexible engine line has been opened at Toyota Kentucky, enabling the facility to manufacture three different engine types at the same time on a single production line. This is the only Toyota plant in North America with this capacity.

The investment comes as part of the OEM’s aim to increase production flexibility in a market transitioning to cleaner forms of mobility. The OEM’s new line will be able to produce 2.4L turbo and 2.5L engines for hybrid Toyota- and Lexus-branded vehicles, with the option to boost hybrid volume to meet market demand.

“With this exclusive new flexible line beginning production, we continue delivering products that meet customer preferences and needs,” said Mark Klee, head of powertrain at Toyota Kentucky. “We are proud of this accomplishment, a direct result of our entire team’s continued commitment to innovation.”

In addition to building engines for vehicles put together at the Kentucky plant, the site also supplies powertrains to six of seven Toyota vehicle plants in North America. As of December 2023, the site will become the only manufacturer of dual-stacked hydrogen fuel cell modules which will be fitted to commercial heavy-duty trucks.

“Our Kentucky team continues to set the standard in innovation and advanced manufacturing,” said Susan Elkington, president of Toyota Kentucky. “Our recent investments are paying off as we are now able to expand the products our facility produces, provide a variety of choices to our customers and lead the company’s electrification plans in the US.”

In 2022, Toyota invested nearly U$3bn in its North American manufacturing operations to support electrification efforts. Toyota Battery Manufacturing North Carolina – the OEM’s newest North American facility – will start to produce lithium-ion batteries in 2025 for use in Toyota hybrid electric vehicles and BEVs.