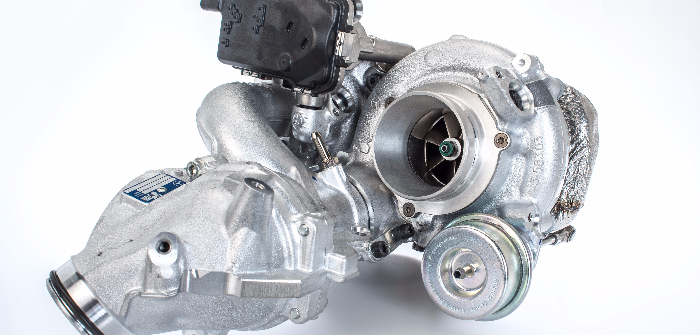

Powertrain component supplier Borgwarner has outlined a supply deal with Daimler, which will see the Tier 1 supplier provide its two-stage turbocharger for the OEM’s 2.9-liter six-cylinder inline diesel engine OM 656.

The innovative technology features a cost-efficient cast steel housing and a new compact design to meet challenging installation geometries.

“Due to its optimized design, our turbocharging solution helps auto makers overcome challenging system placement demands such as a tight fit and high temperatures,” said Frédéric Lissalde, general manager at BorgWarner Turbo Systems.

“We are pleased to support our customers by delivering our highly efficient R2S turbocharging technology to meet the highest possible standards.”

BorgWarner states that its solution is the first on the market to have a cast steel turbine housing. The turbocharger also features a water-cooled e-actuator, bearing housing and compressor housing.

The R2S solution consists of two turbochargers arranged in series – a compact high-pressure exhaust gas turbocharger and a larger waste-gated low-pressure one featuring a ported shroud compressor. This combination means that turbo lag can be kept to a minimum.

As engine speed increases so does responsiveness. The new technology opens a bypass at higher speed, sending nearly all of the gas flow directly toward the low-pressure turbocharger, this then takes over the main compression work to provide high boost pressures with excellent efficiency.