Tier One supplier Honeywell is set to debut an all-new turbocharger on the new BMW 2.0-liter engine program. The move will see the company attempt to ramp up power and torque, while still aiding the reduction of emissions.

The third-generation turbocharger, which the supplier claims will produce power increases from 90kW/l to 100kW/l and in torque from 175Nm/l to 200Nm/l, has been redeveloped for twin-scroll four-cylinder engines that are 1.5-liter or bigger.

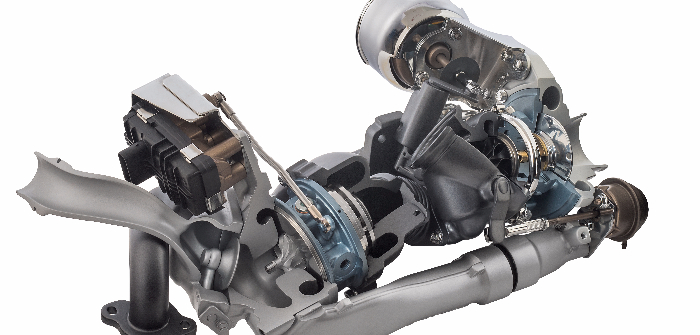

The turbo features an all-new wastegate system, with a redesigned mono-block arm and valve. The upgraded system, which replaces the traditional three-piece valve, results in noise reduction of up to 10dB and a 0.5% improvement in fuel economy.

In addition to this, the Tier One supplier claims the valve design provides better controllability and 50% less wear due to repetitive motion against the turbo housing. Coupled with electric actuation, the wastegate valve reduces engagement time for the catalytic converter, which means emissions are cut down during cold start conditions.

As Honeywell continues to produce turbo technologies for multiple fuels, the Tier One supplier has also introduced the TwoStage Wastegate-VNT diesel engine turbocharger. The newest development, which debuts in the Opel Astra 1.6-liter unit, adds electric actuation for faster response, and a power increase of 17%.

With the automotive industry continues to look to reduce diesel emissions following diesel-gate, the two-stage charger is claimed to help reduce CO2 and NOx by up to 10% and 20% respectively.

Craig Balis, chief technology officer at Honeywell, sees emissions reduction as a main focus for OEMs: “Global automakers are relying on Honeywell to help them manage the increasing emission targets for CO₂ and particulate emissions, and our third-generation gas turbo technology helps them achieve those goals, without sacrificing performance. We have plenty of innovations available and on the horizon for gas and diesel applications – as well as hybrid and fuel cell powertrains.”