A partnership between Eaton’s Vehicle Group, Ballard Fuel Cell Systems and the US Department of Energy’s National Renewable Energy Laboratory (NREL) has been formed targeting the development of heavy-duty truck fuel cell technology. The partnership follows a grant from the Department of Energy to Eaton to support the development of hydrogen fuel cells.

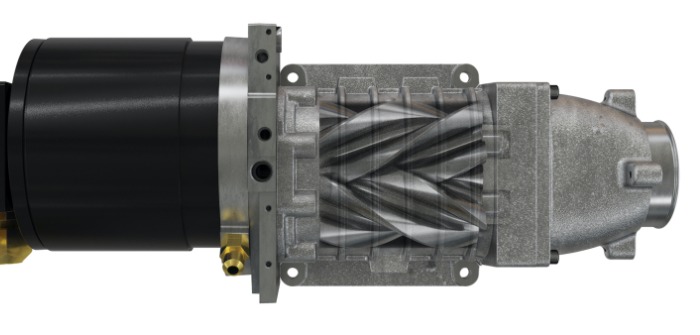

Eaton-owned corporate research labs in Colorado and an additive manufacturing facility in Southfield, Michigan, will be used to produce the fuel cells. To improve fuel efficiency, the latest fuel cell technology will utilize Eaton’s own Twin Vortices Series (TVS) supercharger technology.

“Our TVS supercharger technology provides fuel cell manufacturers with a precise amount of controlled air to increase power and efficiency,” commented Karl Sievertsen, vice president and chief technology officer, Eaton’s Vehicle Group. “The efficiency of competitive fuel cells is lower because most hydrogen fuel cells use simple fans for air flow, which produces less pressure and is not controllable.”

Advanced power electronics and 3D-printing techniques will be used by Eaton, with the company undertaking design and testing of a subscale, proof-of-concept system prototype that will use the TVS technology in order to deliver a significant reduction in air system power consumption and fuel cell efficiency for heavy-duty trucks.

Eaton says that the TVS technology is ideally suited for use in harsh environments due to its tolerance to water, and with operating maps for broad efficiency, it can provide accurate air flow control in proportion to speed. As a result, a water applicator replaces the humidifier in the fuel cell, achieving higher operating pressure ratios and isentropic efficiencies.

“The innovation will be demonstrated in a laboratory setting and will become a springboard for US advanced manufacturing capabilities and technology leadership,” said Sievertsen.