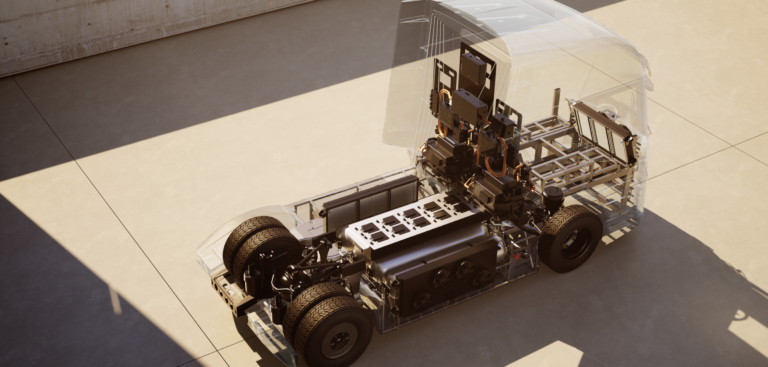

UK-based Hydrogen Vehicle Systems (HVS) has unveiled a modular platform, which it says offers heavy goods vehicle (HGV) operators maximum flexibility from a single base vehicle.

The HGV platform uses the company’s tractor unit and will provide a hydrogen fuel cell powertrain with medium and high-power e-axles, up to three hydrogen tanks and two power outputs– depending on payload and mission requirements.

The modular platform is built on a fixed wheelbase, which means the vehicle’s footprint does not change, irrespective of specification.

The platform enables operators to define their HGV specification relative to their operation and will support the transition to a zero-emission fleet. According to the company, the platform’s flexibility means trucks can easily be retrofitted with alternative modules, such as additional hydrogen tanks, if the fleet’s duties change or expand.

Core electrochemical modules, including the battery and fuel cell, can be swapped out for more advanced equivalents as the technology progresses, which, HVS states, future-proofs the vehicle and increases its potential operational life. Other less-critical components, such as interior trim or body panels, can also be simultaneously refurbished by HVS when a drivetrain upgrade is performed.

The company is also developing new hydrogen drivetrains for its future vehicles, with a focus on delivering maximum power and range for each operational duty class. This should enable operators to transition to a zero-emission fleet in the near future.

Pete Clarke, head of design at HVS, said, “We’re offering maximum modularity within a single base vehicle platform, and we would never have been able to achieve this level of flexibility and optimization with a diesel-powertrain derived vehicle design.

“Our vehicles have been created for a fundamentally different technology within an all-new package, so every cubic millimeter has been designed afresh. We initially calculated the maximum wheelbase possible to achieve the required turning circle and manoeuvrability for the target market. The design process then began with the optimal powertrain format, around which the vehicle design was then created – ensuring that form followed function.”