General Motors has signed a joint development agreement with SolidEnergy Systems (SES) to develop lithium metal batteries for use in its future EVs, and released further details of the company’s next generation Ultium battery technology.

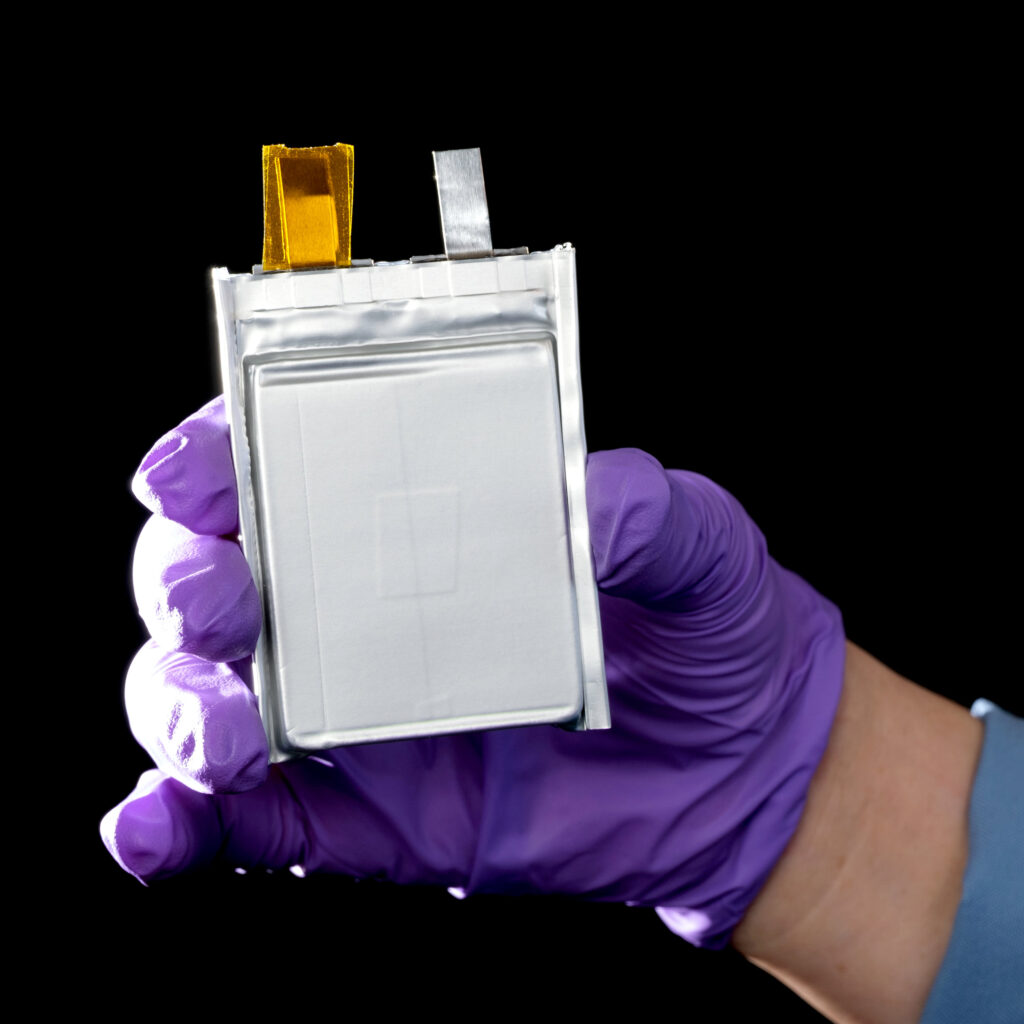

At GM’s Global Technical Center in Warren, Michigan, the newly developed lithium metal batteries have been subjected to 150,000 simulated test miles and feature a protected anode alongside high-performance and energy density, while being produced affordably.

To accelerate the push toward greater fleet electrification, GM has been working in collaboration with multiple specialist companies and making investments that enable the scaling up of EV-related efforts.

It first invested in SES back in 2015, to aid in the optimization of battery technology including lithium-metal battery performance and AI-powered battery management. The recent agreement is a continuation of that first investment and sees both companies planning to build a manufacturing and prototyping line by 2023, set to be based in Woburn, Massachusetts, for use in developing high-capacity pre-production batteries.

Mark Reuss, president of General Motors, commented, “Affordability and range are two major barriers to mass EV adoption. With this next-generation Ultium chemistry, we believe we’re on the cusp of a once-in-a-generation improvement in energy density and cost. There’s even more room to improve in both categories, and we intend to innovate faster than any other company in this space.”

The combined battery development process aims to produce an EV battery with an increased energy density, with a greater range, in a similarly sized or smaller sized battery pack. Through the collaboration between GM and SES, a total of 49 patents have been granted, along with another 45 patents currently pending. GM states the technical advancements are set for possible use in future Ultium-based vehicles, with the first Ultium-platform products estimated to be on sale later in 2021.