Audi has stepped up its research into synthetic fuels, with the company set to develop a new Swiss e-diesel production facility in collaboration with Ineratec and Energiedienst. As the German OEM continues its drive to reduce emissions, the Laufenberg development, in Canton Aarau, will use hydropower to produce over 400,000 liters of e-diesel per year.

“Thanks to the new technology we are able to handle the production of e-diesel efficiently in compact units, making it more economical,” said Reiner Mangold, head of sustainable product development at Audi.

“The pilot facility offers scope for sector coupling, in other words, combining the energy sectors power, heat and mobility, and makes it possible to store renewable energy.”

While Audi has also been conducting research into climate-friendly, CO₂-based fuels such as e-gasoline, the company’s synthetically manufactured e-diesel has the potential to make the traditional IC engine operate almost CO₂-neutrally.

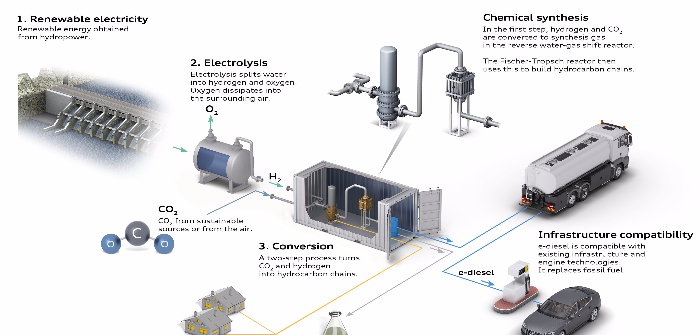

This is thanks to the facility’s power-to-liquid conversion. The green power generated in the hydroelectric power station produces hydrogen and oxygen from water by means of electrolysis. In the next step the hydrogen reacts with CO₂, thanks to microprocess technology. CO₂ is obtained from the atmosphere or from biogenous waste gases and is the only source of carbon. Long-chain hydrocarbon compounds are formed. The final step separates these into the end product, Audi e-diesel.

With a planning application for the development set to be submitted imminently, Audi hope to produce the first quantities of e-diesel in Laufenberg as early as 2018.