Cummins has released details of what it says is the world’s first range of fuel-agnostic engines, which will use engine blocks and core components that share common architectures and will be optimized for different low-carbon fuel types.

“Getting to zero is not a light-switch event. Carbon emissions that we put into the atmosphere today will have a lasting impact. This means anything we can do to start reducing the carbon footprint today is a win for the planet. We need to take action now,” said Srikanth Padmanabhan, president, Cummins Engine Business.

“Having a variety of lower carbon options is particularly important considering the variation in duty cycles and operating environments across the many markets we serve. There is no single solution or ‘magic bullet’ that will work for all application types or all end users.”

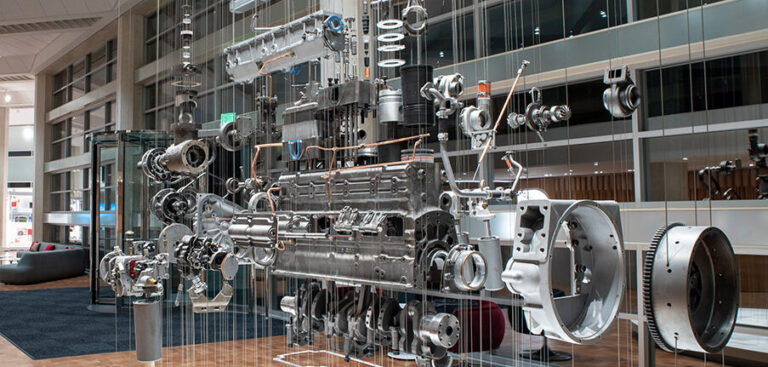

The fuel-agnostic engine platforms will feature a series of engine versions that are derived from a common base engine, including a high degree of parts commonality. Below the head gasket, each engine will largely have similar components and above the head gasket, different components for different fuel types. Each engine version will operate using a different, single fuel type.

The company states that this design approach will be applied across its B, L and X-Series engine portfolios – initially in on-road applications – which will be available for diesel, natural gas and hydrogen.

“Our customers can be confident in Cummins’ unmatched testing and evaluation process ensuring high-performance products,” said Jonathon White, VP of engineering, Engine Business. “No matter what type of work an application does, we’ll have an engine powered by lower carbon fuels with diesel-like performance to get the job done.”