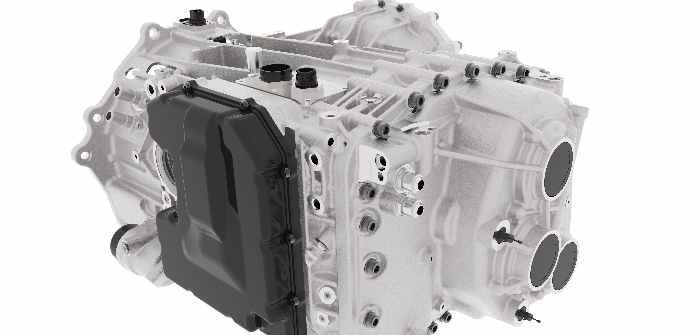

Hofer powertrain, a consortium of companies that includes YASA Motors Ltd and WMG at the University of Warwick, has announced that production of its hybrid transmission for prestige and high-performance vehicles will begin early in 2020. The initial US$34m engineering program, part funded by the Advanced Propulsion Centre (APC), has been running for nine months and is already entering the hardware test stage.

Hofer states that the project has already led to an escalation in enquiries from both local and global customers that require the design and production supply of advanced powertrain products. WMG brings its expertise in power electronics and electric drives to the project. As well as supporting system development and test protocols, WMG is conducting research on increasing the power density of these in the future using wide bandgap semiconductor switching technologies.

Hofer powertrain UK is in the final stages of securing a manufacturing facility that will start up with the employment of 25+ specialist manufacturing staff. It is estimated that due to the growth of hofer in the UK, the supply chain and local infrastructures will benefit by over 200 jobs created or retained.

As well as benefiting the UK economy with new jobs and products it is estimated that by 2022 the technology will reduce vehicle CO2 emissions by tens of thousands of Tonnes.

“This project is very exciting for hofer powertrain, as it allows us to bring our significant experience of electrical, mechanical and software system design and production to the UK market place; working with leading companies to create a unique hofer product portfolio for manufacture in the UK,” explained Johann Hofer, founder of the Hofer Group. “The success of this project and the interest we are receiving from the automotive OEMs, confirms that we took the correct decision when deciding to be part of this project.”