Battery performance is still a limiting factor to the widespread adoption of EVs by the buying public, with range anxiety rightly or wrongly an issue. This applies whether one is building an EV Super Mini or a sportscar such as the Porsche Taycan. The manufacturer of the latter has recently released a summary of its view of the current battery market, drawing on input from both its engineers and experts from third party institutions.

According to Porsche, the reality is that currently, batteries are still a compromise. “For Porsche in particular, high charging performance plays a major role,” says Dr Stefanie Edelberg, engineer at Porsche Engineering. “Sporty driving drains the battery faster, and the customer doesn’t want to have to wait an hour to fully recharge it.”

Unfortunately, as Dirk Uwe Sauer, professor of Electrochemical Energy Conversion and Storage System Technology at RWTH Aachen University, notes, “Battery technology for cars works well in practice, including in terms of performance, charging and service life. However, several extreme properties cannot be combined. You can’t have everything at once.” Ultra-fast charging combined with a high energy density? That’s not possible because the service life would suffer from this combination.

Sauer is therefore skeptical about media reports regarding supposed miracle batteries, because usually a single parameter is optimized at the expense of others. “There will be no universal all-rounder battery,” he says.

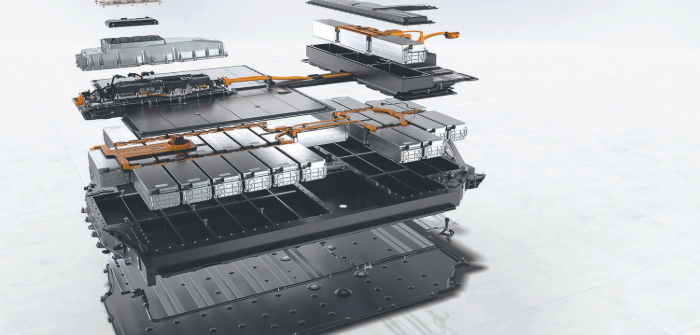

Though other high-energy density, energy storage systems for electric vehicles are under development, lithium-ion cells will remain the technology of choice for the foreseeable future. They have acceptable energy and power density, while also boasting good robustness, which enables them to withstand around 2,000 charging cycles in an all-electric vehicle, at a high depth of discharge, before losing their utility. A figure which could be further improved upon in the future. The consensus at both Porsche and other OEMs being that lithium-ion technology still offers a wealth of development opportunities in terms of cell chemistry and cell design.

For example, according to researchers at the Fraunhofer Institute for Systems and Innovation Research (ISI), energy density has almost doubled over the past 10 years in large-format lithium-ion battery cells for electric cars – to an average specific energy of 250Wh/kg (or 500Wh/l energy density). By 2030, Porsche predicts energy density could increase by a factor of two while other properties of lithium-ion cells can also be improved.

“The biggest challenges are fast charging and safety,” reports Stefano Passerini, director of the Battery Electrochemistry Research Group at the Helmholtz Institute Ulm. “A quick charge to 80% in 15 minutes or less would make electric vehicles even more attractive. However, the safety requirements also rise in conjunction with rapid charging.”

It is not simply battery technology that could limit the potential of EVs. For example, charging plugs, charging cables, and the vehicle infrastructure must also be designed for the high current draw fast charging entails. High currents mean thick cables and therefore weight, hence the move by many manufacturers toward higher operating voltages. This was why Porsche designed its Taycan to run at 800V instead of the 400V common in electric cars.

In order to compare the charging times of electric vehicles with different battery capacities, the C-rate (C stands for ‘capacity’) is a useful metric. It indicates the ratio of the charge or discharge current of an electrochemical cell in amperes (A) to the capacity of the cell in ampere-hours (Ah).

A value of 1 means that complete recharging takes one hour; 2 stands for half an hour, 3 for 20 minutes. The current long-term target at Porsche is a C rate of 10, which means about six minutes of charging time—similar to refueling. It is still someway from this goal, but through the FastCharge research project, involving companies such as Siemens, Phoenix Contact E-Mobility alongside Porsche and others, it is seen as an achievable goal. It should be noted that batteries with a C rate well in excess of 10 do exist, but they have very low power density so are not viable as traction batteries in pure EV applications.

The FastCharge consortium says it has already made great progress. A Porsche research vehicle with a battery capacity of around 90kWh achieved a charging capacity of 400kW, enabling charging times of less than three minutes for the first 100km of range. A complete charging process from 10-80% at the ultra-fast charging station took 15 minutes. C rates of 4 to 5 are therefore feasible. “The decisive factor was an innovative cooling system for the battery, the vehicle and the charging system,” Edelberg explains.

Looking to the future, Porsche expects solid-state battery technology to bring progress in terms of fast charging and safety. These batteries us a polymer or ceramic instead of the liquid electrolyte. Since no liquid is used, the batteries become more compact, which allows their energy density to be increased significantly. At the same time, the cells are less flammable.

“We expect solid-state lithium-ion batteries to reduce safety problems because solid-state electrolytes are less susceptible to fire,” says Passerini. Theoretically, it could also be charged faster. “But the practical feasibility has yet to be proven,” he cautions.