Continental has unveiled details of its new Active Purge Pump (APP) technology, which the Tier One supplier is championing as a ‘new solution to meet stricter hydrocarbon evaporation legislation around the globe’.

As modern gasoline cars use a canister filled with activated carbon to collect all petrol fumes from the fuel tank. The canister, with the cumulated hydrocarbon (HC), needs to be flushed or purged from time to time. The air content, rich in HC, is fed forward to the intake manifold and flows into the combustion chambers where it gets burnt. This system has greatly reduced evaporative HC emissions.

However, two challenges begin to threaten this success story: Firstly, the legislation on evaporative HC emission is set to become much stricter around the world over the next four to five years. Secondly, purging the HC canister is currently done by using the vacuum that is generated in the intake manifold of a gasoline engine during part-load operation by so-called throttling. In highly efficient gasoline cars there is less or no vacuum available, though, because throttling is inefficient and is avoided wherever possible. In a gasoline mild hybrid car the engine may not be running at up to 20% of the driving time, so no vacuum either.

“Continental has developed an electrified solution to further reduce HC evaporative emissions”, said Klaus Hau, head of the Business Unit Sensors & Actuators in the Continental Division Powertrain. “For the first time the Active Purge Pump makes canister purging available independent from engine operation point and vacuum availability. With the Active Purge Pump vehicle manufacturers will be in a much better position to meet oncoming HC emission legislation.”

As the efficiency of modern gasoline cars is partly based on running the engine in the most efficient part of its map whenever possible – or not to run it all, for instance, in a hybrid car. Throttling in particular is avoided as the engine’s thermodynamic efficiency is reduced.

“The need for higher engine efficiency is beginning to make vacuum a rarity in gasoline cars. As a result it is becoming more difficult to flush the HC canister because often the boundary conditions will not allow this,” added Stefan Grüneis, product manager for Continental exhaust and emissions actuators.

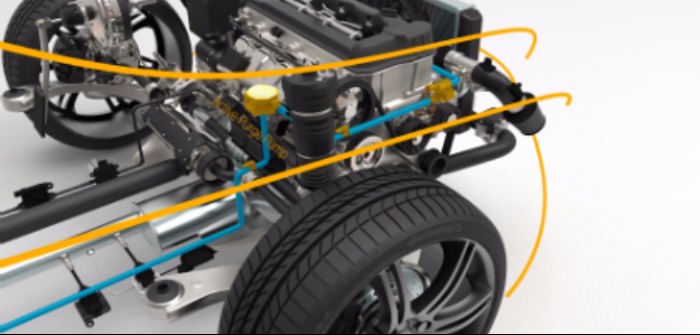

The Active Purge Pump (APP) is not dependent on vacuum. Instead it actively pulls the HC-laden air from the canister. The pump used for this action is a very compact and light-weight radial pump, driven by a highly efficient brushless DC motor.

“The biggest benefit of the APP is that we can use it on demand, and activate it any time when it is necessary”, said Grüneis. “This makes the APP a perfect match for turbocharged engines which are run at higher loads more often, de-throttled engines, start-stop and hybrid powertrains with long engine-off periods.”

Then again, actively purging the canister is only the core function of the new solution. Additional software modules and some additional hardware (like valves) will make further functions available. Among these are a high-performance leak detection and a measurement of the HC content in the purged air.

“Additional functions like these make the pump the core of an Active Purge System (APS). For instance, determining the HC concentration in the purge air is needed to adapt the amount of fuel injection during part load or idling”, Grüneis explained.

Tank leak detection, on the other hand, is currently a stand-alone system which has to be integrated separately. Making this part of an Active Purge System built around the existing Active Purge Pump is more efficient. To support the trend to higher system integration levels, the required APP and APS functional content can be flexibly combined from hardware and software components.