Heraeus High Performance Coatings has unveiled a new method to reduce the gap between rare earth magnet laminates in high-performance electric motors.

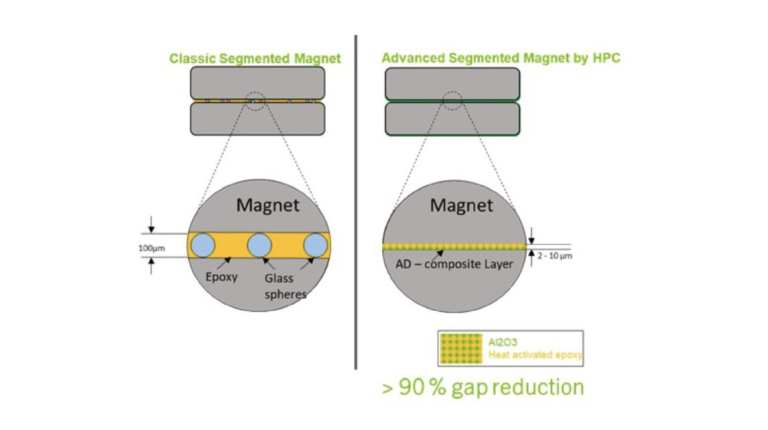

The process relies on aerosol deposition of a compound which combines the properties of an epoxy adhesive with the insulation characteristics of ceramic materials.

Traditional lamination methods achieve a gap of around 50, while Heraeus claims a gap of 2-8µm for its process. The result is a higher volumetric density of magnetic material while speeding the production process, thanks to the elimination of a gluing stage.

Once deposited, the material is thermally activated, providing robust adhesion between the layers while maintaining exceptionally narrow gaps, which the company says surpasses the capabilities of conventional manufacturing methods such as glass sphere spacers, thick epoxy coating and spray paint coating.

“This innovative coating technique by Heraeus opens up new horizons in e-mobility, significantly enhancing the efficiency and performance of electric motors,” said Ilka Luck, head of Heraeus High Performance Coatings. “The reduced gap in stacked rare earth magnets is a game-changer in motor design, aligning perfectly with our industry’s goal for higher motor efficiency and sustainability.”

Click here for more on materials, and here for more on electric motors