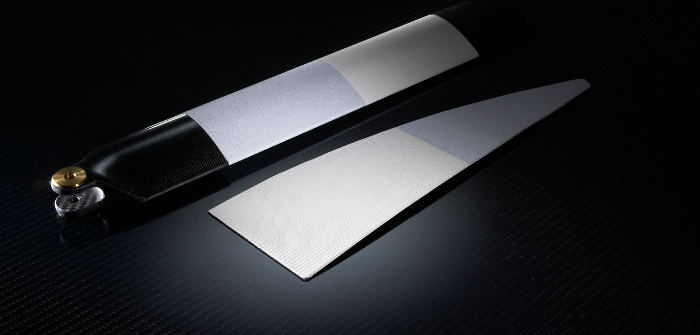

Zircotec Group has developed the first plasma-applied thermal barrier coating that can be used with composites requiring a Class A display surface.

The new technology allows vehicle manufacturers to use the lightweight material in places that have previously not been possible, such as aerodynamic aids near exhaust pipes or the exhaust shrouds themselves.

The technology was developed from Zircotec’s proven plasma-applied ceramic coating at the company’s in-house R&D facility; the chemistry of the compound and the application process have been significantly modified specifically for application to composite materials.

The automotive industry is increasingly adopting composite components, largely to meet strict emissions regulations but also due to consumer demand for the aesthetic qualities of the materials. However, using composites close to heat sources has previously required some form of heat shielding, which adds components and is largely rejected by vehicle manufacturers which are looking to maintain the aesthetics of visible surfaces.

With new manufacturing techniques starting to make carbon composites more affordable, the material is increasingly offering an ideal solution where high strength must be combined with light weight.

Zircotec’s proprietary application process requires specialized equipment and highly trained technicians. The coating has been extensively trialled with a number of Europe’s most demanding vehicle manufacturers and is now available for wider application.