Powertrain business Tenneco has produced a new sintered material that has a greatly reduced cobalt content, while still delivering highly wear-resistant qualities. The new material will provide engine and component manufacturers with an alternative to cobalt.

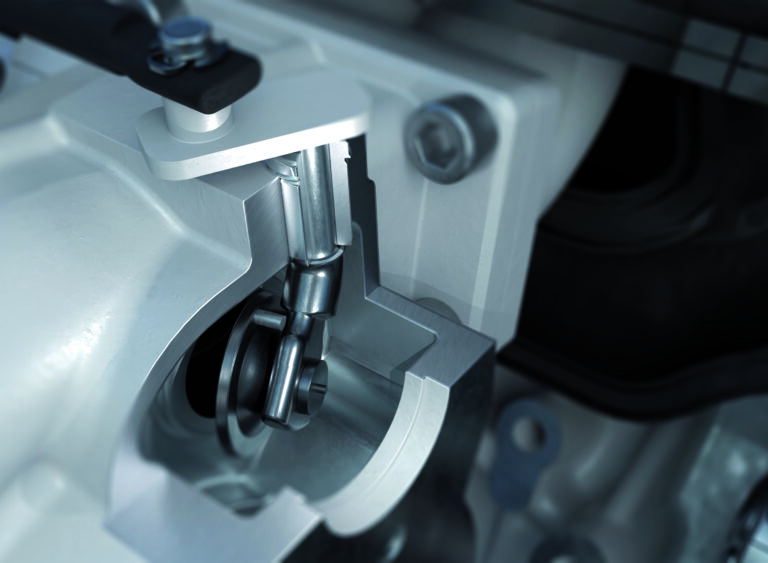

Manufacturer’s typically rely on using cobalt for applications when wear resistance over a wide temperature range from 0°C to 1,000°C (32°F to 1,832°F) is vital, such as high-performance engine valve seats, turbocharger wastegate bushings and EGR valves.

Gian Maria Olivetti, vice president of global engineering at Tenneco, explained, “Potential material shortages and controversy around cobalt mining, coupled with extreme price volatility, mean we must reduce our dependence on cobalt.

“While it remains the most effective material to combat wear in dry running valve seat applications and other components subjected to big temperature ranges, we have used our extensive experience in powder metallurgy to develop a low-cobalt sintered formulation alternative that delivers similar wear properties to the best current materials.”

Research began by selecting two proven sintered products: FM-8100, an iron-based cobalt-free sintered material; and FM-T95A, a cobalt-based sintered material. A series of tests were then conducted by the business using a total of five materials, the two mentioned above containing the lowest and highest cobalt contents.

Based on results and an investigation of worn specimens, it was found the cobalt-containing Tenneco sintered material formed a wear-reducing tribolayer at lower temperatures than a cobalt-free one. After meeting production and quality requirements, the new material – made up of sintered steel with only a 17% cobalt content – was developed and named FM-T88A.

Collaborative trials then took place with a global vehicle manufacturer to compare wear resistance of the new material against series production materials in a test rig containing a turbocharger wastegate bushing running at temperatures around 800°C (1,472°F).

Olivetti concluded, “The results showed that at 200°C, FM-T88A displays a significantly reduced depth of wear compared with a cobalt-free material and is at a comparable level of wear resistance to the high-cobalt material. At all other temperatures the new material’s performance closely mirrored the high-cobalt materials.”