Mahle Powertrain has developed a new 48V battery for MHEV applications, making it possible to maximize the recuperated energy that can be stored and released. Thanks to the improved capability, Mahle claims that mild-hybrid vehicles will be able to achieve a 12% to 15% increase in fuel efficiency.

MHEVs need to recover energy efficiently and at a relatively high power during deceleration, while high storage capacity isn’t necessary as the recuperated energy can be deployed during the next acceleration. Thus, a compact and cost-effective battery that is capable of high charge and discharge power levels relative to its storage capacity is desirable.

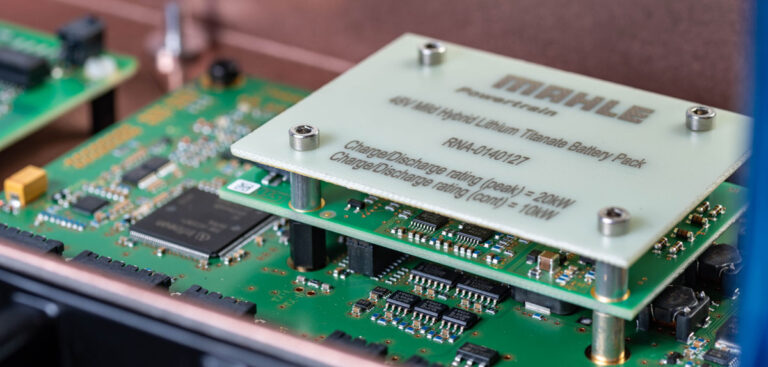

With Mahle’s solution, the LTO chemistry in the selected cells enables continuous charge/discharge rates of 10kW and peak rates for short periods up to 20kW from a battery pack that has only a 0.5kWh storage capacity.

Optimal battery cooling guarantees charge/discharge performance and battery durability. However, the coolant needed to be electrically isolated from the cells. Mahle chose a robust cooling strategy with simulations showing cooling performance to be exactly on target.

During development of the battery, engineers focused on the design of the busbars and electrical connections within the battery, as any high resistance in these components can be an additional heat source and limit the power capability of the system.

Testing of the first prototype is underway to verify that the pack can meet the performance targets. Initial results have indicated that all temperatures within the pack remain within an acceptable range at a continuous discharge rate of over 10kW and that it is capable of peak power levels in excess of 20 kW.

The next step will be to install the prototype pack into the company’s 48V eSupercharged demonstrator vehicle.