Towards the end of 2016, nanoFlowcell Holdings announced that it had successfully achieved variable controllability for its flow cell concept. Following further testing, the company has now announced that its redesigned nanoFlowcell system architecture for electric vehicles is now suitable for series production.

By being able to vary fuel cell control directly, and therefore dispense with the previously necessary supercapacitors, nanoFlowcell Holdings states that it has enabled a significant reduction in the cost and weight of drive systems for electric cars.

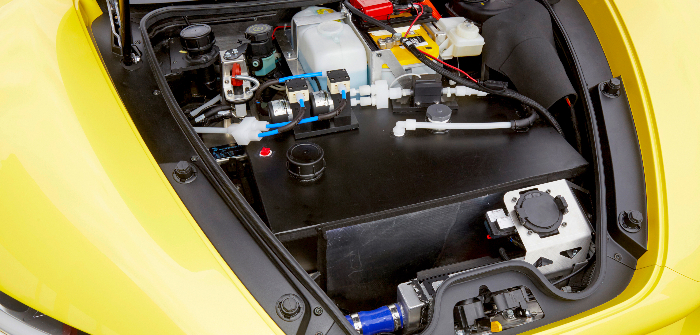

Following nanoFlowcell’s breakthrough last October, the redesigned low-voltage flow cell drive without supercapacitors has been undergoing extensive testing in the Quantino 48VOLT development car. The company states that the benefits of the flow-cell based drive technology compared with other electric drive systems such as lithium-ion batteries or hydrogen fuel cells are ‘remarkable, particularly in respect of power, range, environmental compatibility, cost-effectiveness and safety’.

“The average range of current electric cars stands around the low three-digit mark, with most far from able to sustain motorway speeds for extended periods. Moreover, no car manufacturer is currently making money with electric vehicles – too expensive to produce and sales incentives too high. With the Quantino, we want to show that electric mobility can be different,” explains Nunzio La Vecchia, chief technology officer of nanoFlowcell Holdings. “The Quantino 48V offers not only the range and speed of a regular car with an internal combustion engine, our flow cell vehicle is also more economical and environmentally friendly than any other electric vehicle on the market. It therefore comes as no surprise that our flow cell drive is making a big impression on expert automotive OEMs – at the end of the day, our nanoFlowcell technology opens up completely new horizons in the field of electric vehicle drives.”