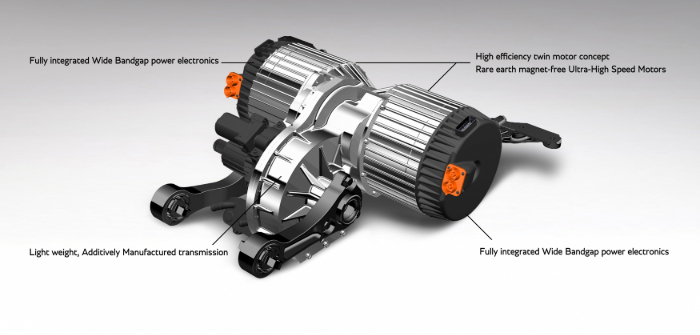

Bentley Motors has announced the commencement of a three-year research study to develop a new generation of vehicle powertrains, which it says will feature a fully integrated, free from rare-earth, magnet e-axle.

The study, titled OCTOPUS (Optimised Components, Test and simulatiOn, toolkits for Powertrains which integrate Ultra high-speed motor Solutions) follows an initial 18-month investigation that Bentley says delivered a technological breakthrough in electric drive systems for high-performance vehicles.

The resulting electric drive system, Bentley says, has exceeded the latest permanent magnet motor performance while simultaneously removing the need for both rare-earth magnets and copper windings, delivering a package that is both cost effective and recyclable at its end of life. Bentley hopes that OCTOPUS will take this motor, power electronics and packaging transmission design through to a production-ready e-axle powertrain.

Commenting on the project, Stefan Fischer, director of powertrain engineering at Bentley Motors, said, “We have made no secret of our ambition to lead the way in the delivery of sustainable luxury mobility, Beyond100. We have a clear roadmap to offer a hybrid option for every model by 2023, starting with the Bentayga Hybrid, and our next goal moves toward a fully electric Bentley by 2026.

“However today, there remains challenges and package constraints on the viability and flexibility of electric vehicle powertrains that are able to fully support EV architectures. With the industry, technologies and cars changing faster than ever before, research projects such as OCTOPUS are crucial to deliver innovative technologies and overcome challenges for the next generation of mobility solutions.”

OCTOPUS is an OLEV-funded project delivered in partnership with Innovate UK, which brings together a variety of industry partners, including companies such as HiETA Technologies which specializes in additive manufacture of motor components; Talga Technologies, which is developing next generation motor winding materials; and the Advanced Electric Machines Group, which was responsible for the initial proof of concept motors.

Advanced Electric Machines Group CEO Dr James Widmer, said, “Having already worked closely with Bentley to successfully deliver a proof of concept, we look forward to this new project to push the performance, packaging and sustainability of electric vehicle drives to a new level, removing the need for rare-earths and copper and achieving the highest levels of system integration.”

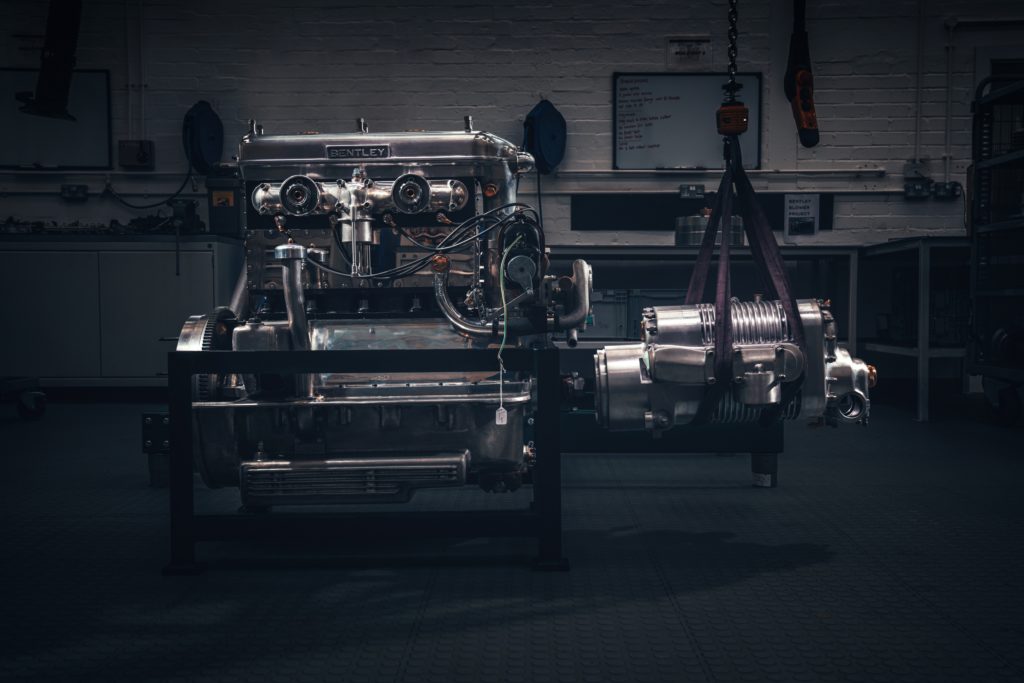

Meanwhile, the company is also undertaking a project that is the opposite of forward-looking EV development – the construction of a continuation line of its legendary, 4.5-liter Blower Bentleys.

The Blower Continuation Series will be a 12-car run of 4.5–liter Bentleys built to the unique design of Bentley’s own 1929 Team Car, developed and raced by Sir Henry ‘Tim’ Birkin. The 12 cars together form the world’s first continuation series for a pre-war car, and all have been pre-sold.

The project includes the recreation of the all-new versions of the cars’ 4,398cc engines, which were advanced for their time, featuring overhead camshafts with four-valve-per-cylinder heads, augmented by a Villiers roots type supercharger. Construction of the engines is currently underway and Bentley said each will be proved out on one of the company’s in-house test benches, specially adapted to the task.