Ferrari has released details of its latest mid-rear-engined Berlinetta, the 296 GTB. The 296 GTB pairs plug-in electrification tech with an all-new V6 turbo – the first 120° six-cylinder to feature in a Maranello road car.

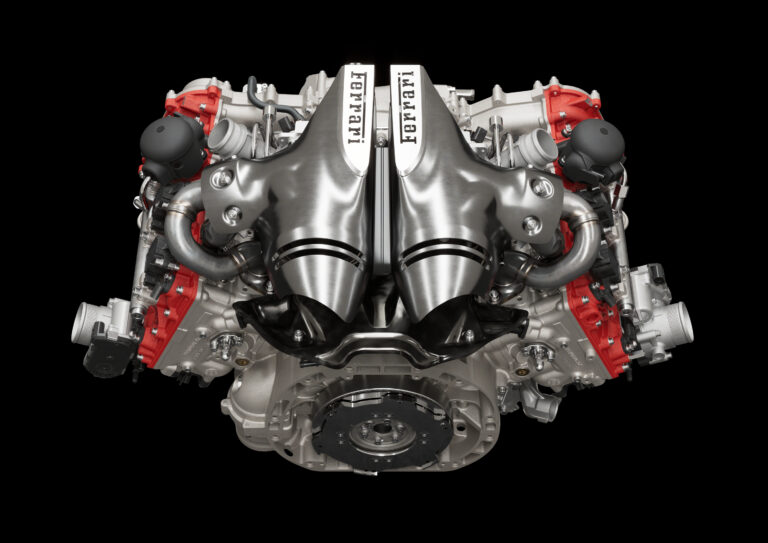

Engineered from a clean sheet, the first engine in the F163 family is configured with the turbos installed inside the vee and with equally spaced firing for a more compact engine design and optimally distributed mass. The result is a claimed specific power output record for a production car of 224ps/l. Maximum output of the 2,992cc motor is 672ps and its rev limit is 8,500rpm.

To obtain this output, combustion pressure had to be pushed. To that end, Ferrari employed its expertise in alloys, dimensioning and components to develop a new, specific aluminum block and cylinder heads.

The V6 also benefits from the central injector and spark plug with 350-bar pressure injection system that first featured in the SF90 Stradale, while the intake and exhaust ducts were redesigned and tuned to maximize volumetric efficiency and thus ensure high levels of turbulence in the chamber.

To increase maximum revs of the mono-scroll turbochargers to 180,000rpm, Ferrari collaborated with IHI to allow a complete redesign using higher performance alloys. This improved performance and a 24% increase in boost efficiency.

Ferrari developed a new variable displacement oil pump to guarantee that the oil pressure is continuously controlled right across the engine’s entire operating range. A solenoid valve, controlled by the engine ECU in a closed loop, is used to control the pump’s flow and pressure.

Ferrari developed a new variable displacement oil pump to guarantee that the oil pressure is continuously controlled right across the engine’s entire operating range. A solenoid valve, controlled by the engine ECU in a closed loop, is used to control the pump’s flow and pressure.

On the oil scavenge side, to minimize splashing losses, the suction system was made more powerful using six scavenge rotors: three specific dedicated rotors for the crankcase below the crank throws, one for the distribution compartment and two for the cylinder head compartments.

Traditionally, in Ferrari engines, the intake plenum is located in the center of the vee. However, the plenums on the F163 V6 are on the side of the cylinder heads and are integrated with the support for the throttle valve. This solution boosts performance thanks to shorter ducts, and reduces time-to-boost due to the high-pressure line’s smaller volume.

The new architecture also led to the development of a more linear exhaust line in the upper part of the engine. The linear shape reduces back pressure and contributes to boosting performance. The exhaust manifold and catalyzer housings are made entirely from Inconel, a steel-nickel alloy to reduce weight and make it more resistant to high temperatures.

In addition to the six-cylinder – codenamed ‘piccolo V12’ during development – the powertrain assembly comprises an 8-speed DCT, e-diff, and an MGU-K located between the engine and the gearbox. A clutch is set between the ICE and the dual-rotor single-stator axial-flux electric motor to allow decoupling for electric-only driving. Lastly, there is a high-voltage battery and the inverter which controls the electric motors.

The 296 GTB is also the first Ferrari to feature a rear-wheel drive-only PHEV architecture in which the ICE is integrated with a rear-mounted electric motor producing up to 122kW. The electric motor and ICE communicate via the Transition Manager Actuator (TMA) to allow a combined power output of 841ps or decoupling for the electric motor to run solo.