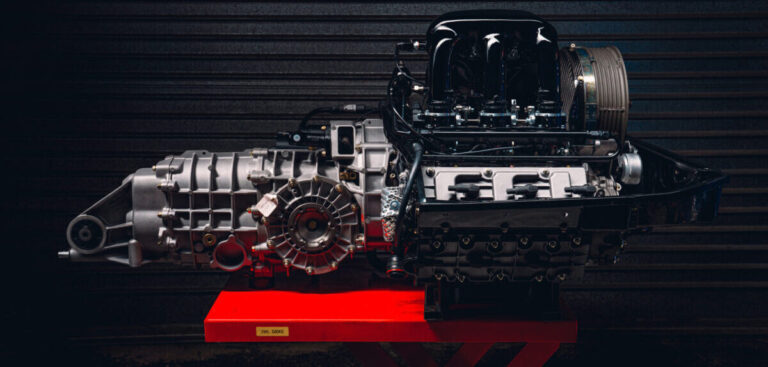

UK-based Porsche 911 specialist Theon Design has given a glimpse of its next bespoke Porsche 964-based commission, with a first look at the car’s 450bhp supercharged version of the famous air-cooled flat-six.

“It’s what we refer to as OEM+,” explained company founder Adam Hawley. “With obsessive attention to detail and state-of-the-art technology, we elevate the Porsche 911 experience to another level for our customers, applying that approach to every part of the car from the exterior to the interior and the engine – the very heart of the car.

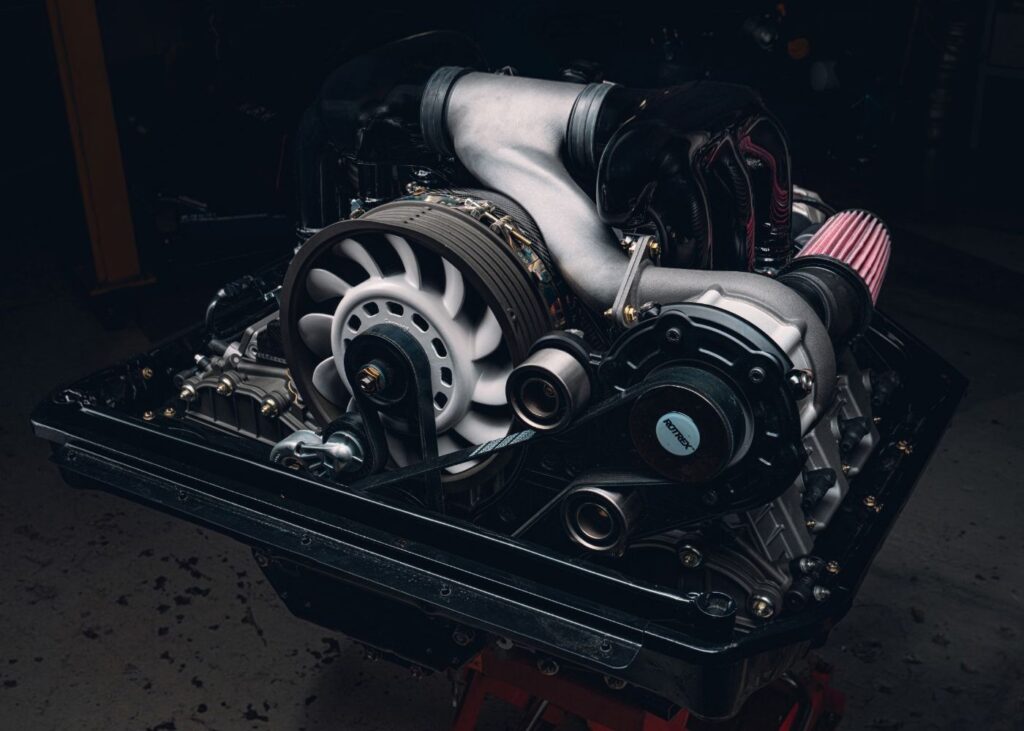

“We wanted to deliver additional performance but also maintain the seamless delivery of a Porsche naturally aspirated engine, so chose a Rotrex centrifugal supercharger. Effectively a belt-driven turbocharger, it gives a wonderful, linear power delivery and instant throttle response with no delay or lag. It was crucial to us that the Porsche flat-six sound was undiluted and we’re very pleased with the results: the supercharger has a very subtle ‘whine’, so the flat-six is still front and center, with some wonderful added character.”

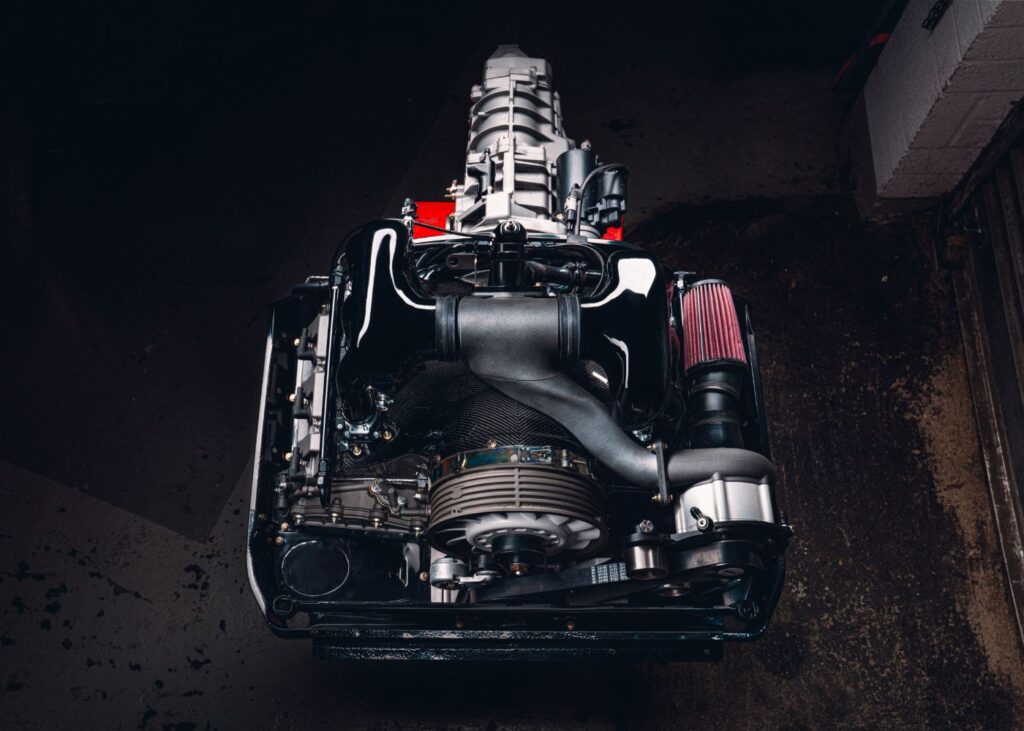

Hawley noted that the Rotrex supercharger also offers excellent integration and compatibility: “As every Porsche enthusiast knows, there’s not a great deal of room within the 911 964 engine bay, so we located the supercharger in the space previously taken up by the original air-conditioning unit.”

To achieve this, the team utilized some of the engine’s existing AC brackets to further support the unit, developing and designing additional bracketry to mimic the design and materials used for the engine cam covers and other elements. Significant effort was undertaken to ensure this would provide solid and durable support for the supercharger, allowing for no movement or flex, no matter how extreme the driving conditions, from a bumpy mountain road to a high-speed race circuit.

To maintain a ‘clean’ look to the engine bay, Theon Design opted for a water-methanol injection system, negating the need for an intercooler and air intake apertures in the bodywork.

“Injecting a water-methanol mix into the engine plenum not only provides the same cooling function as an intercooler but also increases the octane rating of the fuel, boosting 98 octane petrol to a 110 rating and improving performance as a result,” said Hawley. The methanol supply system is integrated with a 3D carbon printed section to bridge the plenums, complementing the carbon-fiber engine and fan shroud.

“Injecting a water-methanol mix into the engine plenum not only provides the same cooling function as an intercooler but also increases the octane rating of the fuel, boosting 98 octane petrol to a 110 rating and improving performance as a result,” said Hawley. The methanol supply system is integrated with a 3D carbon printed section to bridge the plenums, complementing the carbon-fiber engine and fan shroud.

The engine is equipped with a new, simplified and lightened motorsport specification wiring loom with a single autosport connector allowing for straightforward engine removal. Theon has also replaced the distributor caps with coil packs, which not only further tidies the engine bay but also provides a better spark.

Theon Design partners with air-cooled Porsche 911 engine specialist Nick Fulljames on all of its engines.

“The Porsche air-cooled flat-six is a remarkable unit, engineered and constructed to precise standards no other manufacturer could match,” enthused Fulljames. “When you strip one down, you find it has been built to the exact same tolerances as all the others. The engine is superbly robust and provides the ideal building block upon which to create additional performance if that is what the customer requires. Porsche built this engine with that flexibility engineered in, in the first place, as it was originally homologated for racing purposes, and so, with the application of modern technology, it’s perfectly adaptable to receiving large power increases.

“We’ve had decades of experience developing motorsport-inspired camshafts and tailoring them to precisely match the induction, exhaust system, cylinder head and bore size of each of the engine configuration choices on offer,” revealed Fulljames.

Ensuring a flexible power delivery was one of the key requirements for the engine. “Finding the balance and creating the sweet spot is the key,” continued Fulljames. “We use the generation one and generation two Porsche 911 GT3 models as benchmarks. That’s the kind of power delivery and driving experience we want to create – really tractable low down, with superb response when revved.”

Ensuring a flexible power delivery was one of the key requirements for the engine. “Finding the balance and creating the sweet spot is the key,” continued Fulljames. “We use the generation one and generation two Porsche 911 GT3 models as benchmarks. That’s the kind of power delivery and driving experience we want to create – really tractable low down, with superb response when revved.”

Depending upon the configuration chosen by the customer, the company states that engine build time varies between 150 and 250 hours. All engines spend a minimum of four hours on the dyno to bed in and to verify power and torque outputs, but that is merely the beginning of the testing process.

“Road testing is key to ensuring perfection,” said Hawley. “Each commission is driven over a huge variety of road conditions, from town centers, B-roads, A-roads and motorways. Every car must be as happy being driven at crawling speed around a busy supermarket car park as it is at high speed. It’s that OEM+ attention. It’s a passion for perfection. Many days are spent with Nick, tweaking the control mapping on each engine on the road, just to make sure it provides an optimum response in every possible driving scenario.”