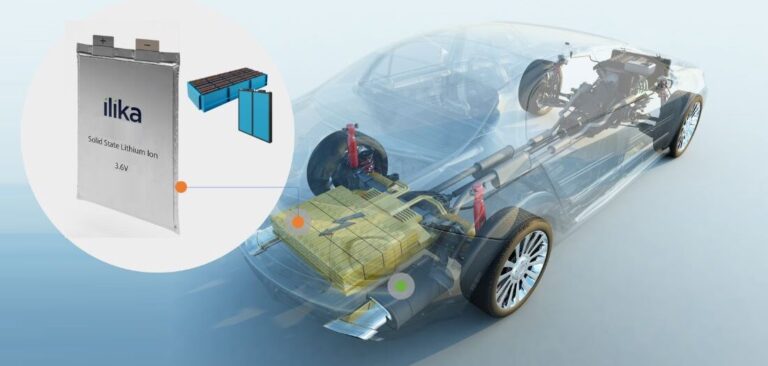

Industrial automation company Comau and solid-state battery technology provider Ilika are to collaborate on a 12-month, Advanced Propulsion Centre-funded (APC) project to scale up Ilika’s lab-based manufacturing capacity. The aim is to increase the solid-state battery pioneer’s production rate from 1kWh per week to 10kWh per week at its pilot facility.

There are also plans for Comau to conduct a feasibility study of Ilika’s Goliath solid-state technology process, as well as work on designs for a manufacturing strategy that can be cost-effectively scaled to reach mass production levels.

The two companies believe that Comau’s approach to smart automation will enable the selection an optimal combination of systems that can meet aggressive throughput and time to market goals, in addition to meeting replicability targets.

Graeme Purdy, CEO of Ilika, added, “Comau is a leader in industrial automation and plant design with a strong track record in the battery industry. This project represents an exciting opportunity to work with Comau’s experts in designing a robust and scalable manufacturing strategy for our Goliath solid state batteries.”

As Goliath is a next-generation technology, Comau intends to use its design and battery competencies to propose an innovative solution that meets unique requirements.

“We are honored to be working with Ilika to bridge the gap between prototype manufacturing and commercial production of next-generation batteries,” added John Coombes, managing director, Comau.

“Our progressive approach to simultaneous engineering along with Comau’s cutting-edge solutions and investments further strengthen our ability to speed development of promising new technologies.”