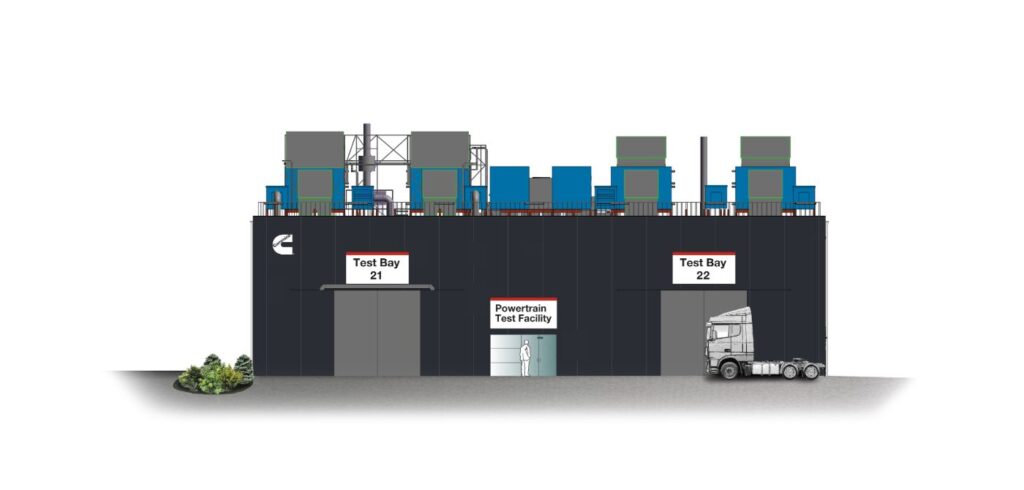

Heavy-duty engine manufacturer Cummins is to create a new powertrain testing facility in Darlington, UK, with a focus on the development of low-emission powertrain concepts.

The facility, which is due to open in 2023, is designed to be fuel-agnostic and will enable Cummins to develop and test a wider range of power technologies, including the latest universal engine platforms with variants able to operate on green hydrogen, renewable natural gas, or sustainable diesel. Installation and testing capability will also extend to hydrogen fuel cell and battery electric powertrains.

The facility will include dynamometers capable of testing not only powertrains, but also chassis-installed powertrains and vehicles, extending in size from a compact SUV to heavy-trucks over 44 tons. Off-road equipment, including construction machines and agricultural tractors, will also be accommodated.

“We are very excited to announce this significant investment in the new Powertrain Test Facility at Darlington, which will be an important element in Cummins Destination Zero strategy to deliver a broad portfolio of power solutions to meet the world’s sustainability challenges,” said Jonathan Atkinson, executive director of Cummins On-highway Business in Europe. “The new facility will further enhance the ability of Cummins European Technical Operations to introduce low-to-zero carbon power solutions and meet the forthcoming Euro VII very low emission regulations, likely to take effect around 2025.”

Covering a 738m2 footprint, the two-story facility will also generate its own sustainable power. The heavy-duty dynamometers and test cells will feature energy recovery systems to generate electricity. This will be exported to the ring main of the Cummins site, adding further capability for energy self-generation on-site. In addition, water consumption of the cooling towers will be reduced by harvesting rainwater, using a similar system already in place at the co-located manufacturing plant.