USA-based engine manufacturer Cummins has signed a multi-year deal with simulation specialist Ansys, which it says will help further research related to improving emissions profiles, performance and other attributes of diesel and alternative fuel engines.

Ansys states it will aid Cummins engineers in their development of new engine designs, empower enterprise-wide collaboration and support initiatives related to Planet 2050 — Cummins’ environmental sustainability strategy that aims to reduce greenhouse gas and air emissions.

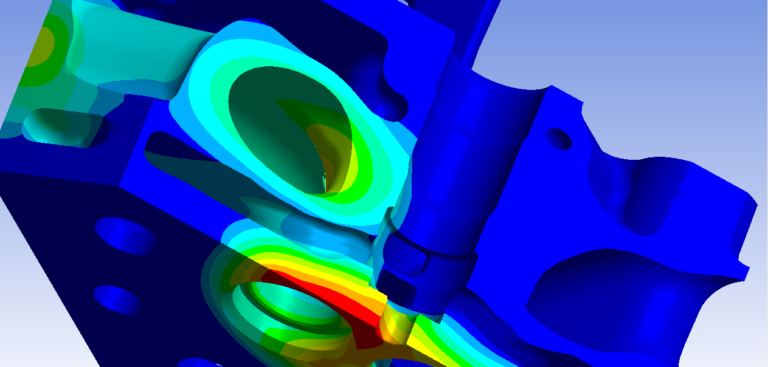

Through the collaboration, Cummins will leverage Ansys’s tools and next-generation simulation process and data management (SPDM) platform to expedite the development. Specifically, by utilizing physics-based digital twins Cummins hopes it will enable its engineers to make product health management decisions that reduce the cost and risk of unplanned downtime and improve product development processes.

“Cummins continues to support its customers by investing in R&D to ensure next-generation engines are more fuel efficient than ever. A key R&D partner for more than 25 years, Ansys has accelerated our digital transformation and ingrained simulation into the DNA of our company, enabling us to rapidly and accurately deliver engines with improved emissions profiles and other environmental attributes,” said Wayne Eckerle, vice president, Research and Technology, Cummins.

“This new agreement introduces leading-edge tools which will help us develop a shared knowledge infrastructure, explore a larger design space, virtually validate products, improve engine quality and reduce development costs.”