UK-based engineering company D2H Technologies has developed a battery simulation technique that helps a major OEM with an EV fast-charge challenge presented by one of its production vehicles.

The company’s approach harnessed both its battery simulation and correlation capabilities, which enabled battery thermal management enhancements to be assessed in fast-charge scenarios. Through these studies, the OEM has been able to reduce excess noise caused by high coolant pumping rates, while also improving heat dissipation within its batteries.

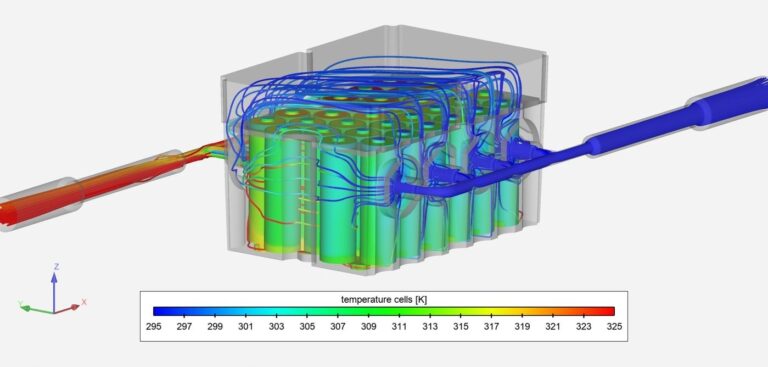

Working in partnership with chemical supplier Croda, whose fluids were used in the cooling system, a 32-cell battery test rig was built where the performance of newly developed versus contemporary cold-plate cooling methods could be evaluated, in addition to a CFD (computational fluid design) model to help conduct comparative studies examining the cooling capabilities of other fluids.

During the first stage of the project, D2H explored the cause of excess noise during a battery fast-charge, which was identified as the high pump power required by the existing cooling system. Further CFD modeling during the development process showed benefits of using a Croda-manufactured dielectric fluid compared with alternative options.

A second investigation was launched to find differences in the performance characteristics of immersive and cold plate cooling systems using the same simulation correlation process. According to D2H, the results demonstrated that the dielectric fluids provided more efficient heat transfer and fewer hot spots and demonstrated more stable characteristics, thus helping to create a more efficient battery for use in EVs.

D2H engineering director Chris Hebert stated, “Battery performance is a critical aspect of inspiring further take-up of EVs and it is a technology that is still in its relative infancy. During development, all areas of battery performance must be considered, especially their behavior during high C-rate charging and discharging when in situ.

“The work with Croda in considering different types of chemical as a battery coolant has provided valuable insight that has not only helped to overcome an existing challenge but generated vital data that can streamline the development of new, more efficient EVs. Providing enhanced thermal management of the battery has the potential to offer further accelerated fast-charge times in the future.”

Kyle Thompson, part of the energy technologies team at Croda Europe, added, “Through our work with D2H, we are delighted to demonstrate the tangible benefits and possibilities of using new ester chemistry in an automotive application. Bringing forward the ban on the sale of new petrol and diesel cars to 2030 means that advancing vehicle electrification has never been more crucial. Providing efficiency benefits to existing battery technologies is only the first stage and we look forward to showcasing the potential of refined cooling techniques on next-generation vehicles.”