The National Composites Centre has announced a major new R&D investment program. A total of US$45.9m will be invested in 10 new composite technologies, tailor-made to the NCC’s specifications, in order to quicken the development of new processes and provide a boost to the UK automotive, aerospace and construction sectors.

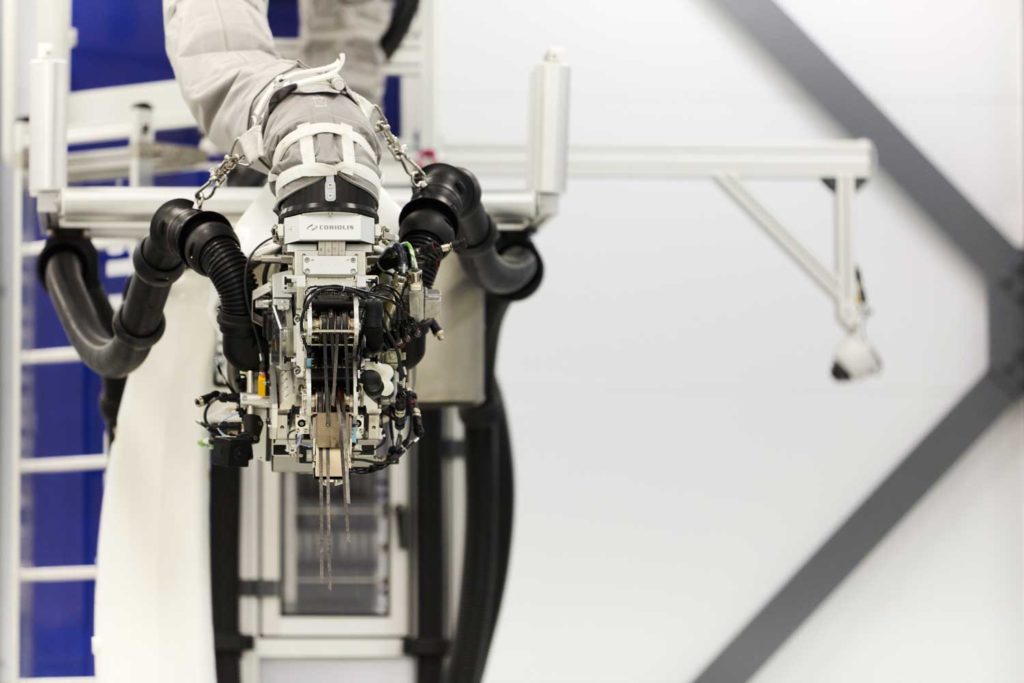

Funded, in part, by the Aerospace Technology Institute (ATI), the Digital Capability Acquisition Program (iCAP) hopes to bring composites into the digital age, increasing production rates and quality, while improving efficiency and reducing cost.

NCC partners will be given access to next-generation technology and be able to test new techniques alongside the NCC’s expert team. The ultimate aim is to help companies boost productivity and secure the UK’s position at the forefront of high-value manufacturing.

With global demand for composite products expected to increase by 4.1% each year from 2018 to 2023, it is predicted that the market will be worth US$105.8bn by 2020, up 55% from 2013, as the world looks for new materials to produce lighter, more fuel-efficient vehicles.

It is hoped that the automotive industry – with manufacturers demanding one-minute cycle times and production-line-ready parts straight out of the mold – will benefit from improved technology in high-speed injection molding, overbraiding and automated forming methods.