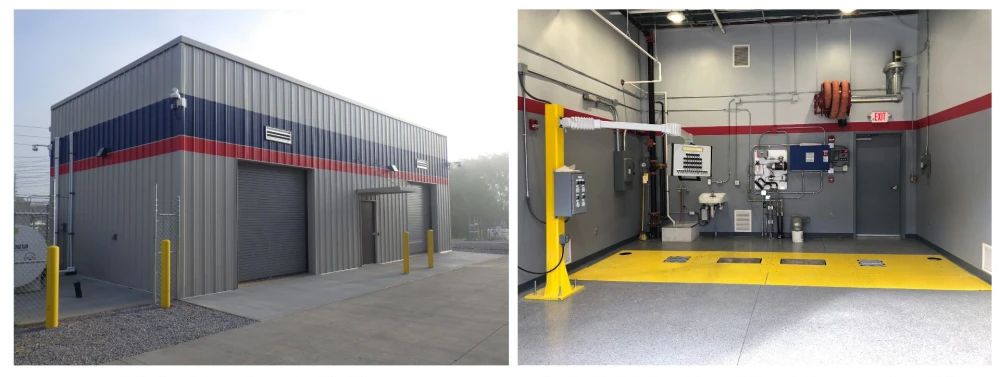

Tennessee-based Tuff Torq Corporation , which manufactures hydraulic and hydrostatic drive systems for the turf care, agriculture, construction, off-highway and marine industries, has invested in increasing its on-site testing capabilities with the addition of a zero-turn mower chassis dynamometer and purpose-built dynamometer facility.

The company’s test department has been working closely with a dynamometer manufacturer in Michigan to design and build equipment that will be used specifically for testing commercial and residential zero-turn mowers. Testing can be performed on gas, diesel and electric mowers with the ability to generate specific vehicle load conditions, while recording vehicle data.

The fuel and exhaust systems are designed to enable continuous 24-hour testing in temperature-controlled environments, facilitating thorough evaluations. Using an AC Pulse Width Modulated Vector Control System, the setup ensures full four-quadrant operation, ideal for simulating “road load” scenarios, says Tuff Torq.

The system has been designed for residential and commercial zero turn mowers and enables vehicles to remain stationary during testing, to enhance observation, data collection and video recording capabilities to replicate real-world field conditions accurately.