Engineering simulation software developer ANSYS has announced the acquisition of 3DSIM, developer of additive manufacturing simulation technology. The deal provides the engineering company with an entry point into what is a fast-growing market segment.

“Additive manufacturing is changing the way companies are bringing products to market, and 3DSIM is helping to lead the way through its innovative solutions,” said Shane Emswiler, vice president at ANSYS.

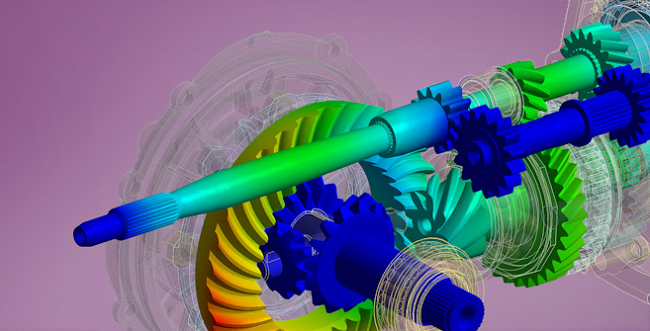

“By bringing exaSIM and FLEX onto our Workbench platform, ANSYS can offer customers the only end-to-end additive manufacturing simulation workflow available. That will spark innovation, speed time to market and reduce manufacturing costs for our customers across industries.”

With companies looking to replace existing manufacturing methods, additive manufacturing technology has the potential to transform the industrial manufacturing landscape. To enable the optimization of metal density, metal printing is utilized.

However, the laser used often melts the metal in unexpected ways, causing product failure. Additionally, rapid heating and cooling can cause stresses that can deform the product. The combined ANSYS-3DSIM simulation solution aims to mitigate those risks, leading to stronger, yet lighter future components.

Based in Park City, Utah, 3DSIM’s simulation software enables manufacturers, designers and engineers, to achieve their objectives through simulation-driven innovation rather than physical trial and error.

“We are excited to become part of the ANSYS family with its near 50-year history of helping customers realize their product promise,” added Brent Stucker, CEO at 3DSIM.

“Combining 3DSIM’s leading additive manufacturing technology with ANSYS engineering simulation solutions will be a win-win for our customers and the entire industry.”