After 10 years of development; Ricardo, in collaboration with spin-off company Dolphin N2, has unveiled its CryoPower engine technology concept as the company looks to achieve superior thermodynamic performance.

The all-new liquid nitrogen cooled ‘split-cycle’ engine promises 20% greater fuel economy and a 30% reduction in CO2 emissions.

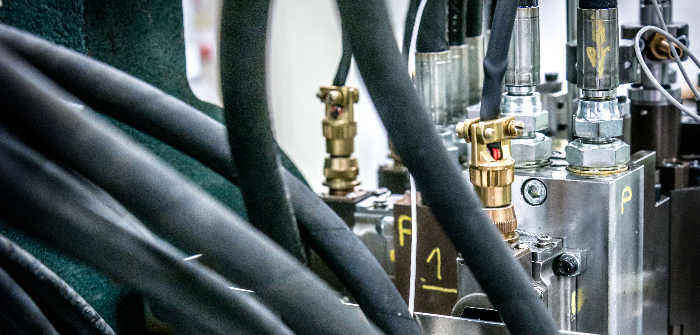

The technology, which is designed for heavy-duty applications, uses a separate induction and compression cylinder to recover wasted exhaust heat and produce working gas after the end of compression. The compression process is carried out isothermally, cooled via the injection of a small amount of liquid nitrogen.

The liquid nitrogen therefore acts as both a coolant and an additional energy vector, which offsets fuel requirements. This means the internal thermal efficiency of the IC is improved in comparison with today’s state-of-the-art engines.

Utilizing either renewable or traditional fuels, the combustion process delivers heat energy back to the chilled and compressed intake air, thus helping to achieve improvements in fuel economy, reduced CO2 and other emissions.

“The development of the conventional heavy-duty engine is reaching the point of diminishing returns with regard to fuel efficiency and CO2; to go significantly beyond the current state of the art requires a completely new approach,” said Simon Brewster, CEO of Dolphin N2.

“CryoPower offers a step-change improvement in both fuel efficiency and operating fuel cost, and the prior development of its crucial enabling technologies has significantly reduced development risk.”

To further the CryoPower technologies, Ricardo has formed the company Dolphin N2, which will lead the project and are looking for further investment to enable commercial development.