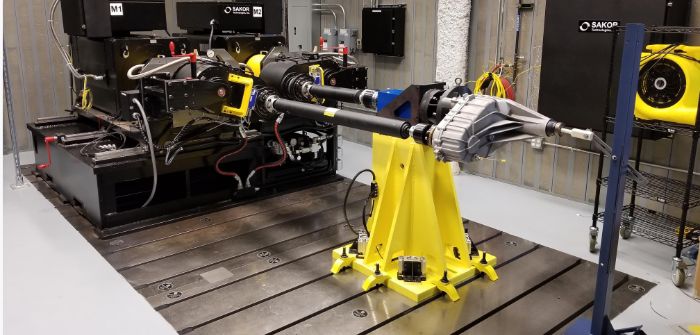

Sakor has supplied a new torque transfer test stand to an international powertrain component supplier. The system has been developed to test clutches, transfer cases and torque transfer devices.

The powertrain test stand will be used for testing torque transfer components in small passenger to medium industrial vehicles. The system, one of six built by Sakor, features dual 420kW dynamometers that can operate at up to 6000rpm.

In addition, the dynamometer system offers maximum continuous torque of 4,010Nm, with up to 150% overload for up to 30 seconds. The test stand can be adjusted to any transfer case/torque transfer device geometry.

The test stand is controlled by Sakor’s DynoLAB data acquisition and control system, which provides fully automated test procedures for testing protocols.

“The new test stand has been built for maximum flexibility and adjusts quickly and easily to any transfer case system being tested,” said Randal Beattie, president of Sakor. “It takes minimal operator time to set up and install test units, so what used to take many hours and long drive shafts can now be done in a matter of minutes.”