The French OEM has been using Siemens PLM’s Simcenter Amesim simulation software to optimize its transmission design process and avoid late-stage issues.

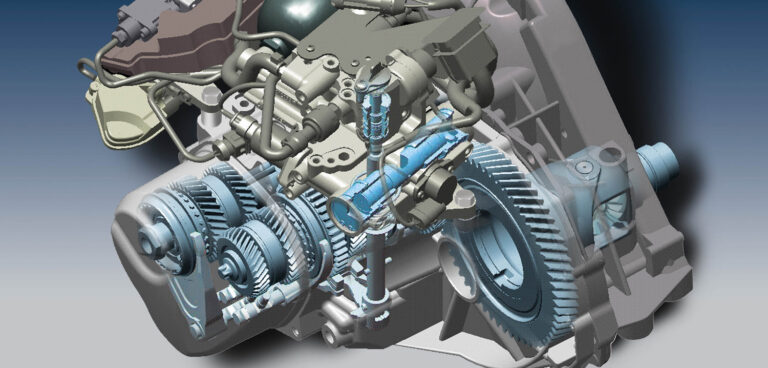

One of the features consumers increasingly look for in a new car is an automated manual transmission (AMT). These combine the fuel efficiency, performance and control of manual systems with the convenience of automatics.

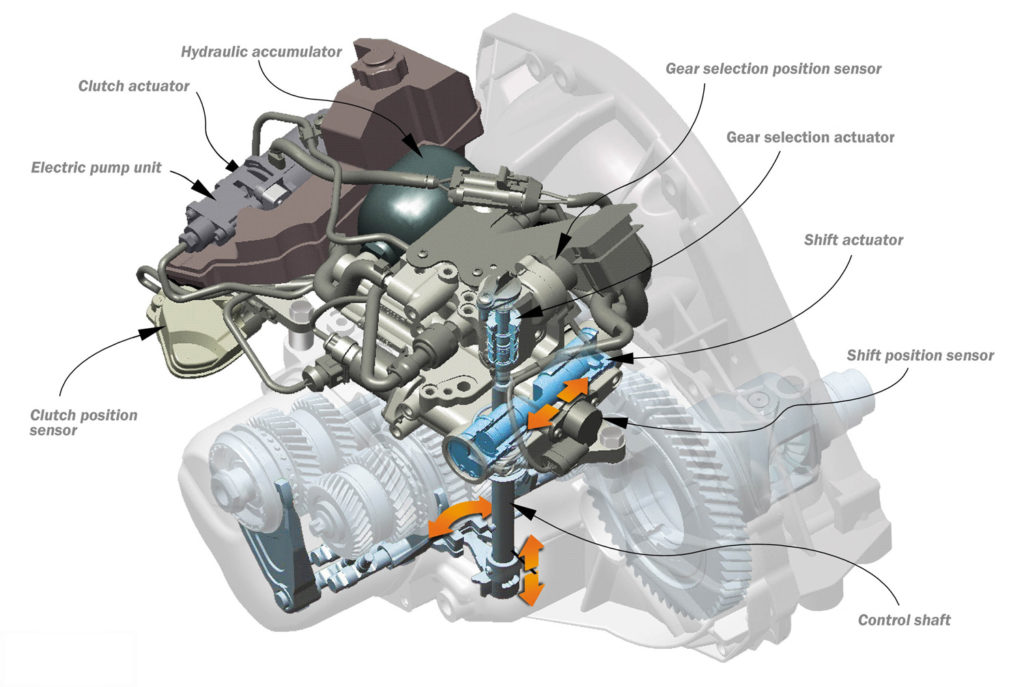

With the automotive industry still experiencing challenging times, car makers are focusing considerable development effort on cost-effective, smooth-shifting AMTs. However, these complex mechatronics systems are difficult to design because their performance depends on the operation of three different subsystems all working together in perfect synchronization: an electromechanical actuator that shifts the gears, electronic sensors that monitor vehicle status, and software embedded in the transmission control unit (TCU).

Ordinarily, it takes up to a year to define the overall functional requirements, design the actuator mechanics, develop and calibrate TCU software, and validate the complete system. Software development and calibration present particularly troublesome bottlenecks since these tasks typically require extensive trial-and-error physical testing cycles that cannot be performed until hardware prototypes are built.

By then, mechanical and electronics designs are nearly finalized and cannot be changed appreciably to improve powertrain performance. Considerable time is also spent troubleshooting problems near the end of the design rather than refining TCU control strategies.

To meet approaching vehicle launch deadlines, engineering teams must often settle for an overall design that barely meets application requirements rather than one that optimally balances mechanical, electronics and software performance.

In a pioneering initiative, French auto maker Renault is streamlining the AMT development process with a simulation-based approach using Simcenter Amesim software, a 1D simulation solution for predicting the performance and functionality of complex multi-domain systems using a single, unified physics-based model.

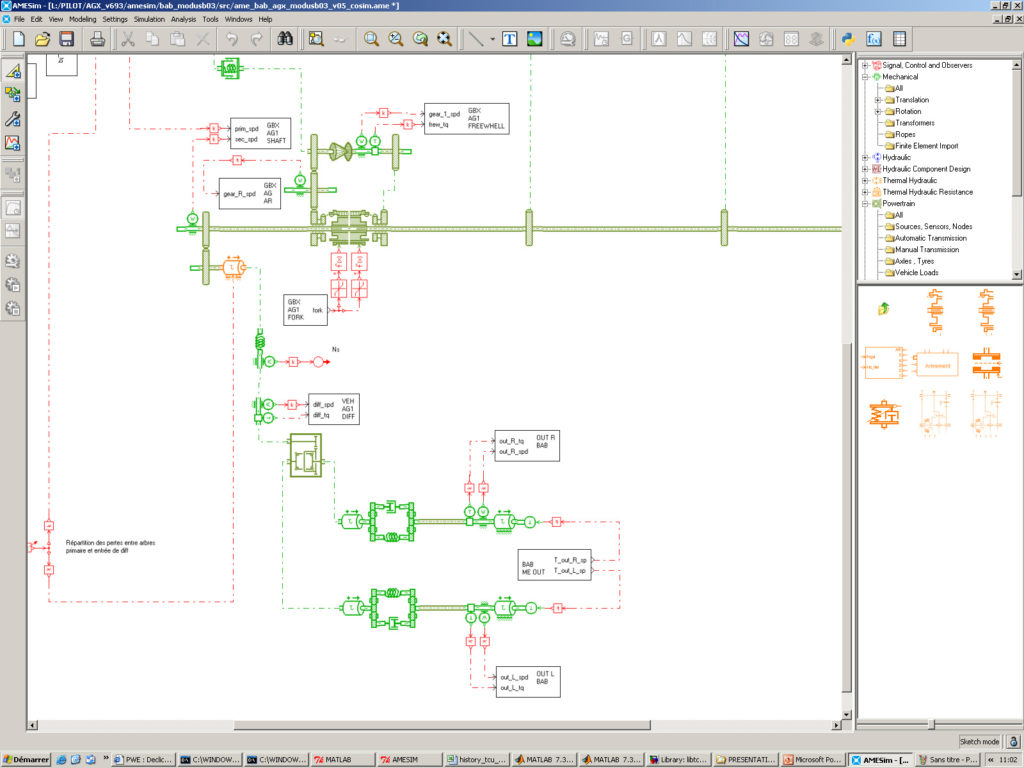

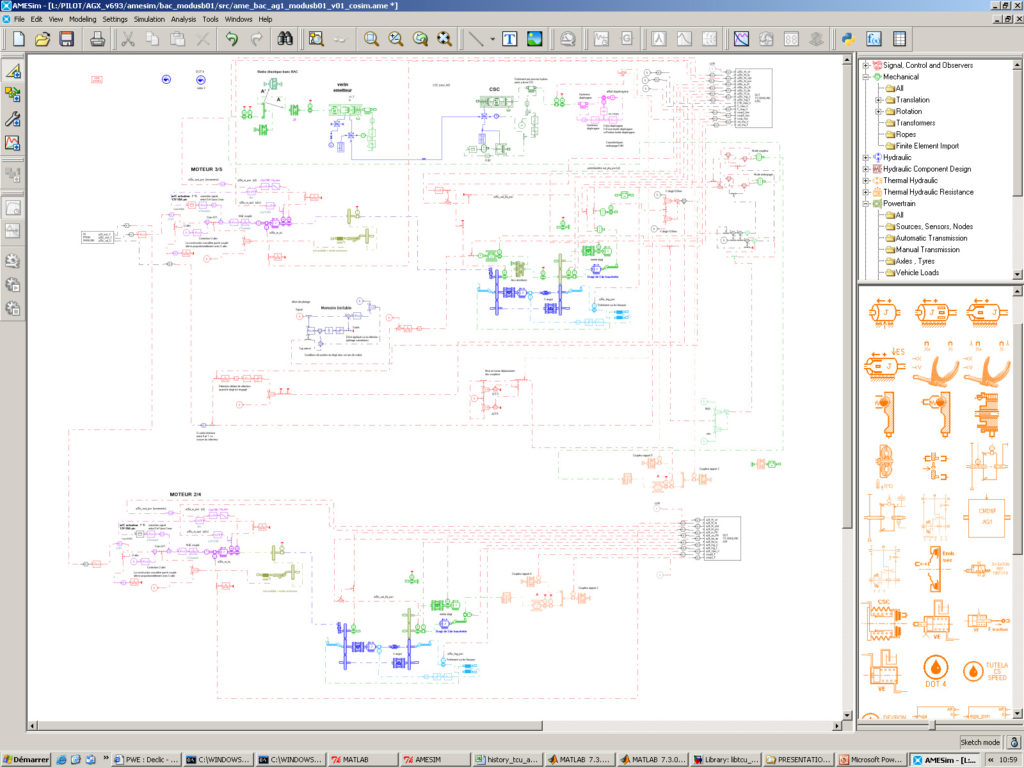

Engineers drag, drop and interconnect simple icons to graphically create the model displayed on the screen with a working sketch showing the relationship between all the various elements to predict the behavior of the entire AMT system.

“By using the multidomain simulation approach based on Simcenter Amesim, we can see early in development how all the various parts of the complex AMT system will operate together: mechanics, electronics and control software,” said Edouard Négre, senior design engineer in the Renault Powertrain Control Engineering Division. “With this understanding of the complete mechatronics system, we can readily optimize the entire design up-front in development and avoid many late-stage problems and delays.”

Throughout the process, the model created evolves as the design progresses and system requirements are defined in greater detail. Renault most recently used the method to develop a new actuator for one of its existing AMT models, redefine the existing TCU control strategy, and evaluate the entire AMT performance.

A simplified model was initially created to define overall powertrain load constraints and size the major mechanical components, including hydraulics, electric generator and gear reductions. Next, parameters from design drawings and technical data from engineering specifications were added to plot overall performance curves, define basic control commands and determine the overall response of the complete mechatronics system.

In these conceptual phases, engineers explored the behavior of various alternative mechatronics configurations – including actuator designs to provide for smooth gear shifting – until the best powertrain performance was achieved.

Based on these simulation results, the model was then used to develop control algorithms that served as a basis for performing co-simulation between Simcenter Amesim and the real-time software development and integration platform to develop first-order TCU logic software.

Simcenter Amesim was used to simulate the powertrain hardware in this software-in-the-loop (SiL) approach, essentially providing a virtual engine and transmission as stand-ins while the actual hardware was still in development.

Finally, the TCU software performance was validated and calibrated using a hardware-in-the-loop approach to exercise the system model in real time. On a test rig, a TCU with control code embedded in the electronics sent signals to operate a physical prototype of an AMT actuator based on simulated load and sensor signals generated by Simcenter Amesim for the rest of the powertrain.

In this way, engineers finetuned the TCU software to achieve optimal powertrain performance according to fuel efficiency, dynamic response and other operational factors.