Driveline engineering specialist, Drive System Design (DSD) will present two technical papers in parallel sessions tomorrow, on 18th May, at the International CTI Symposium, held in Novi, Michigan, USA. The papers underline some of its cutting-edge developments in both product design and the evolution of advanced engineering techniques.

“One paper shows how mass can be reduced and NVH improved through a novel composite transmission casing design; the other presents agile methodologies for integrating control system simulation more effectively into the development process,” explained Jon Brentnall, DSD’s vice president, Engineering. “Though the subjects are each quite distinct, they both illustrate our commitment to finding industry-leading solutions to emerging challenges.”

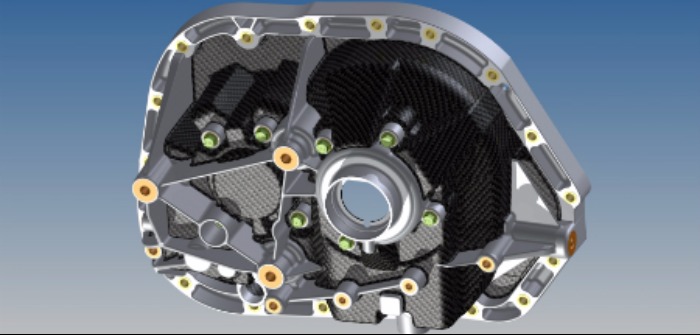

The first paper will present the technical issues considered during the concept design of a radically new transmission casing architecture, the benefits it provided and the challenges that remain. Key design strategies to enable the use of composite materials in volume production will be presented, together with recommendations for additional transmission components and sub-systems that could utilise the technology.

In addition to saving over 30% in weight, compared to a conventional casing, the new design has superior modal damping, which improves NVH and enables friction to be reduced by using highly efficient gear designs that would produce unacceptable excitation in a traditional casing. Entitled ‘Composite Transmission Housing Design: combining mass reduction and improved NVH’, the paper will be presented by Jon Brentnall.

The second paper shows how the use of customised simulation tools can mitigate the risks inherent in control system development, illustrating the methodology with a case study.

Control system development does not fit well within the ‘gateway’ driven programs commonly used in the automotive industry, which are defined by hardware development cycles. The paper shows how efficient simulation models can be customised to meet the simulation requirements of the control engineering team, which vary through the maturity cycle of the product, using an agile approach based on continuous incremental iterations that build and improve, with quick validation and empirical feedback.

This allows a control system program to exploit agile methodologies to reduce overall program risk, cost and time to market, but requires an understanding of both the simulation techniques available and software development needs. Entitled ‘Control System Development: Agile methodologies through customised simulation models’, the paper will be presented by Pedro Zabala, Principal Engineer, Control, DSD.