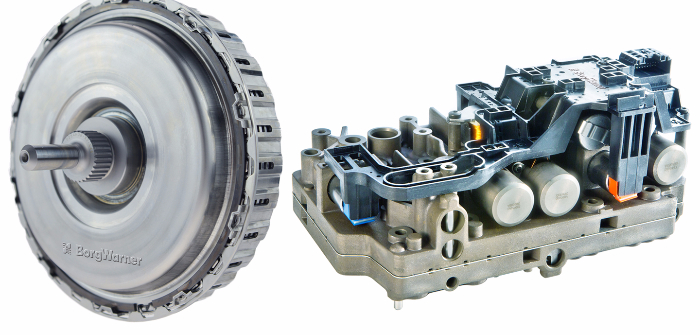

BorgWarner has released details of the customized DualTronic clutch and control modules that use advanced solenoid valves and friction materials, for Chinese OEM Great Wall Motors (GWM).

The application of BorgWarner’s technology is in GWM’s self-developed wet dual-clutch transmission (wet DCT). Designed to improve fuel efficiency and provide a dynamic driving experience, BorgWarner’s dual-clutch module and control module feature improved heat resistance, scalable torque capacity and tunable launch characteristics. GWM’s specially designed 7-speed wet DCT will initially be available for GWM models such as the just-launched WEY and other models.

“With increasingly stringent emissions standards and higher fuel economy requirements, many Chinese domestic automakers are embracing technologies that offer greater fuel efficiency and environmental benefits,” said Robin Kendrick, president and general manager, BorgWarner Transmission Systems. “This March, we began mass production of our customized dual-clutch and control modules for GWM. We are pleased to help our customers meet China’s energy saving and environmental protection policies by providing professional technology support. Since we reached a strategic partnership with GWM in 2013, BorgWarner has been dedicated to assisting GWM with its growth in the Chinese automotive market. We will continue to work closely with GWM to help achieve their future goals.”

BorgWarner’s DualTronic clutch module features a specially developed groove design; the module’s advanced multi-segment wet friction materials provide improved heat resistance while delivering high torque capacity and reliable operation over the transmission’s lifetime. Using compact electro-hydraulic solenoid valves, the control module precisely regulates the clutch as well as the transmission’s gearshift actuation system for dynamic performance. Its compact and modular design also contributes to fuel efficiency by reducing the length and weight of the gearbox. By improving fuel efficiency, DualTronic technology also contributes to reduced emissions for OEMs.