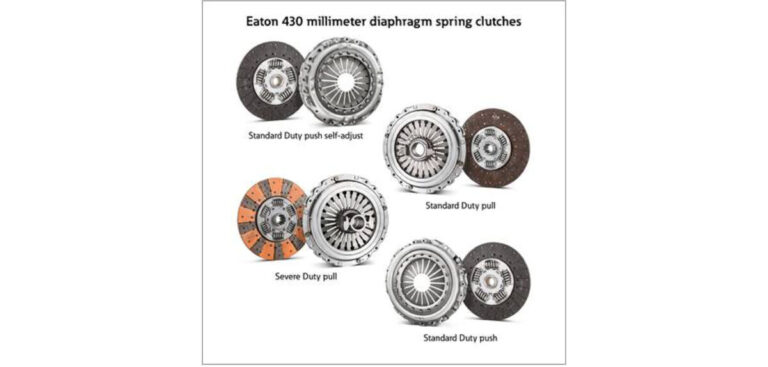

Eaton has announced that its Vehicle Group has added new products to its 430mm diaphragm spring clutch portfolio, intended for heavy-duty commercial vehicle applications.

These will feature the company’s latest technologies to increase component durability, alongside excellent noise, vibration and harshness (NVH) attributes.

The new components are said to offer solutions for a range of current and future powertrain advancements, including downsized and downspeed engine setups. These newer engines produce peak torque at lower RPMs, creating higher levels of engine torsional vibration, so Eaton’s new 285mm-diameter damper clutches are designed to deal with such vibrations through heavy-duty application of its Soft Stop technology. This increases clutch durability by reducing the stresses on damper springs during potential over-torque scenarios.

Heavy-duty diesel engines often use 232mm or 254mm-diameter dampers, which manage engine vibrations traveling through the vehicle driveline from the clutch into the transmission and down the driveshaft into the axles. This reduces the chance of damage and improves driving characteristics.

“Eaton diaphragm spring clutches provide OEMs with integrated solutions that meet NVH and longer-life requirements,” commented Scott Davis, business unit director, commercial powertrain in Eaton’s Vehicle Group. “The new Standard Duty, Severe Duty and Extreme Duty designations within our portfolio allow us to provide a comprehensive line of clutches to our OEM and aftermarket customers.”

A push self-adjust design is included on Standard Duty models and is primarily designed for on-highway applications like line-haul and regional delivery. The 430mm push self-adjust design has an organic face to provide clean releases, smooth engagements and faster gear shifts. The push self-adjust design is available in a new 2,650Nm and 2,800Nm torque rating model, and a 254mm damper with 2,500Nm torque rating version. Furthermore, a new push self-adjust Extreme Duty clutch is now available in 254mm and 285mm damper sizes with a 2,650Nm torque rating; it features higher thermal capacity alloy components and an optimized pressure plate mass for improved durability and enhanced low-speed maneuverability.

The Extreme Duty clutches use a new organic facing and a more robust pilot bearing, and have been designed with frequent starts and stops in mind. The improved durability characteristics help to provide 63% more actuations than standard temperature versions.

Severe Duty models are also available in the product portfolio and feature a ceramic face for vocational applications; they are available in a 232mm damper size with torque ratings from 2,200Nm to 2,500Nm.

“We’re always looking at market trends, customer needs and technology advancements to continuously improve our portfolio. By expanding our diaphragm spring clutch portfolio, our aim is to help customers pursue new powertrain advancements today and well into the future,” said Davis.