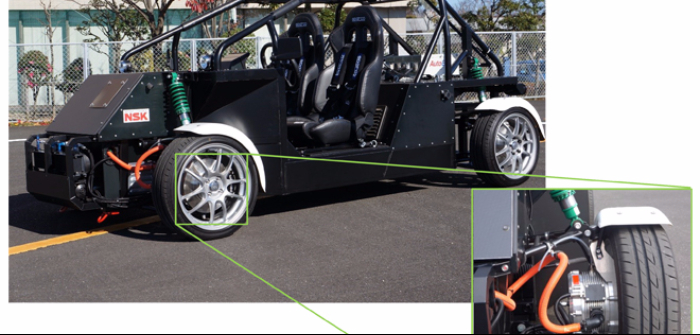

NSK Ltd. has announced that it has successfully demonstrated the world’s first transmission-equipped wheel hub motor. Building on the knowledge it has gained from its prototype wheel hub motor, NSK is aiming to commercialize wheel hub components such as the hub unit bearing with built-in speed reducer, the one-way clutch unit, the miniature cage and roller bearing, and the anti-corrosion bearing.

The company says the unit is a response to the increasing awareness of environmental problems and the continual need for improved efficiency and performance. In-wheel motors that can work with various drive systems independent of the body structure of automobiles are increasingly attracting attention as next-generation drive devices.

An in-wheel motor located near the wheel can reduce the weight of the vehicle body by reducing powertrain parts such as engines, controlling the drive force of each wheel, and expanding the size of the cabin space, thereby improving environmental performance, safety, and comfort.

However, NSK outlines that there is a problem in terms of enlarging the size of the motor in order to achieve both the large drive torque necessary for acceleration and hill climbing and a sufficient maximum speed. For such reasons, this technology has not been put into practical use until now. The technology for a more compact in-wheel motor is one of the most important technologies for improving environmental performance, safety, and comfort.

The all-new unit from NSK is equipped with two motors and a transmission composed of two planetary gears, which can achieve both high drive torque and a sufficient maximum speed with a small motor. In addition, this transmission has a feature that enables smooth gear changing even during acceleration by controlling the speed and torque of the two motors. For the first time in the world, NSK demonstrated the superior performance of this technology using an experimental vehicle equipped with a prototype wheel hub motor.