Packaging space is increasingly under pressure in modern vehicle designs, as engineers cram evermore equipment into platforms. In an effort to address this challenge from the perspective of transmission manufacturers, Vitesco Technologies has announced the release of a new, compact transmission control unit manufacturing process.

The company claims that, in comparison with conventional control units, its new process, known as overmolding control electronics, results in TCUs with 45% less weight, greater robustness and significantly fewer production stages.

“Vitesco Technologies is not only one of the drivers of electric mobility, but we also consistently and continuously focus on innovation in our electronic products,” explained Wolfgang Breuer, head of the electronic controls business unit at Vitesco Technologies. “The overmolding control unit, which has now gone into serial production, is another testament to the pioneering work that we are doing in the interests of forward-thinking mobility and sustainable growth.”

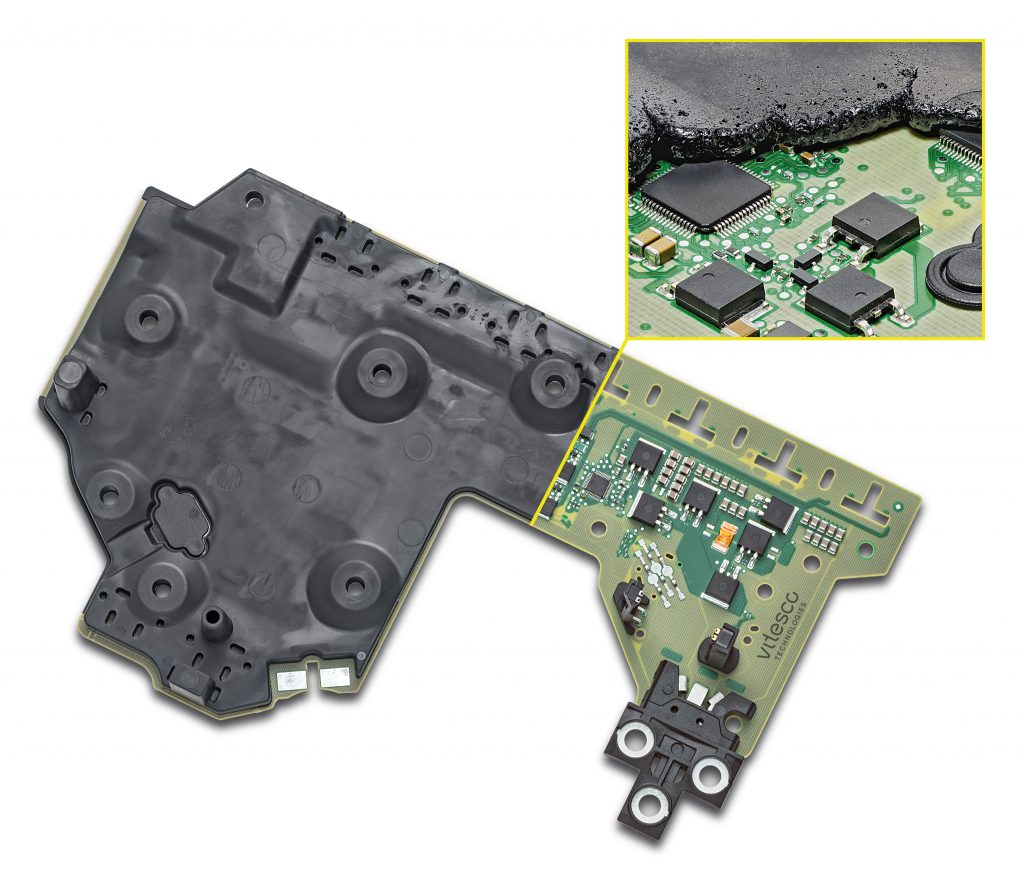

In a conventional ECU, the electronics are located within a housing. With an overmolding ECU, the electronic components, which are arranged on a printed circuit board as is normally the case, are completely embedded in plastic. Vitesco says that high-precision injection molding processes as well as new, particularly resistant plastics has enabled worldwide serial automobile production of this type of ECU for the first time.

The company says its manufacturing process offers several advantages over traditional methods. Firstly, because of the extreme robustness of the components – with the sensitive components completely enclosed in plastic – they can better withstand strong vibrations.

Secondly, an overmolding component is not only lighter than a comparable ECU in a conventional housing, but also significantly flatter. The transmission control unit developed by Vitesco is claimed to currently be the flattest on the market, with a thickness of only 7mm. The control unit used until now was 15mm thick. Additionally, the company notes that an overmolding component can be produced using considerably fewer production stages than a housed electronic control unit.

“For Vitesco Technologies, the overmolding process is a key new technology that we will be using as quickly as possible for further electronic control units. We are registering a high level of interest from automobile manufacturers. The development of new overmolding electronics is already underway – above all for use in hybrid and electric vehicles,” added Breuer.