Following UK MPs calling for the ban on sales of new gasoline and diesel cars to be brought forward by eight years to 2032, Chris Brace, professor of automotive propulsion at the University of Bath’s Institute for Advanced Automotive Propulsion Systems, discusses the IC engine’s future.

“It is entirely practical to bring forward the date by which conventional vehicles are no longer on sale, but the mix must continue to include hybrid and plug-in hybrid,” said Brace. “These vehicles – especially the latter – can be effectively zero emissions in cities but still meet the diverse needs of rural residents, commercial users and long-distance drivers.”

While a report from parliament’s business select committee criticized cuts to subsidies and the lack of charging points, the committee’s chairwoman, Rachel Reeves MP, said the UK government’s targets gave “little clarity or incentive to industry or the consumer to invest in electric cars”.

Professor Brace added, “The recent reduction in government incentives shows that we cannot, and should not, rely on the government to drive this change by financial interventions. It must be shaped by legislation but driven by customer benefits.

“Consumers must be willing to pay their own money for the benefits that these new vehicles offer. This ultimately must apply to both the vehicle itself and the infrastructure that it needs to operate.

“This means that we need to do a significant amount of R&D to improve this offer by reducing purchase and operating costs, and improving the practicality of the emerging alternatives. This is an essential enabler to making the changes we need in a market led economy.”

As part of the push to reduce emissions, SAIC Motor UK Technical Centre and the University of Bath have formed a joint investigation to identify the most efficient conditions for gasoline particulate filters to help minimize vehicle impact on the environment.

The GPF Burn rate and Low Temperature Reactivity project will last 14 months and utilize the university’s state-of-the-art chassis dynamometer in its Centre for Low Emission Vehicle Research.

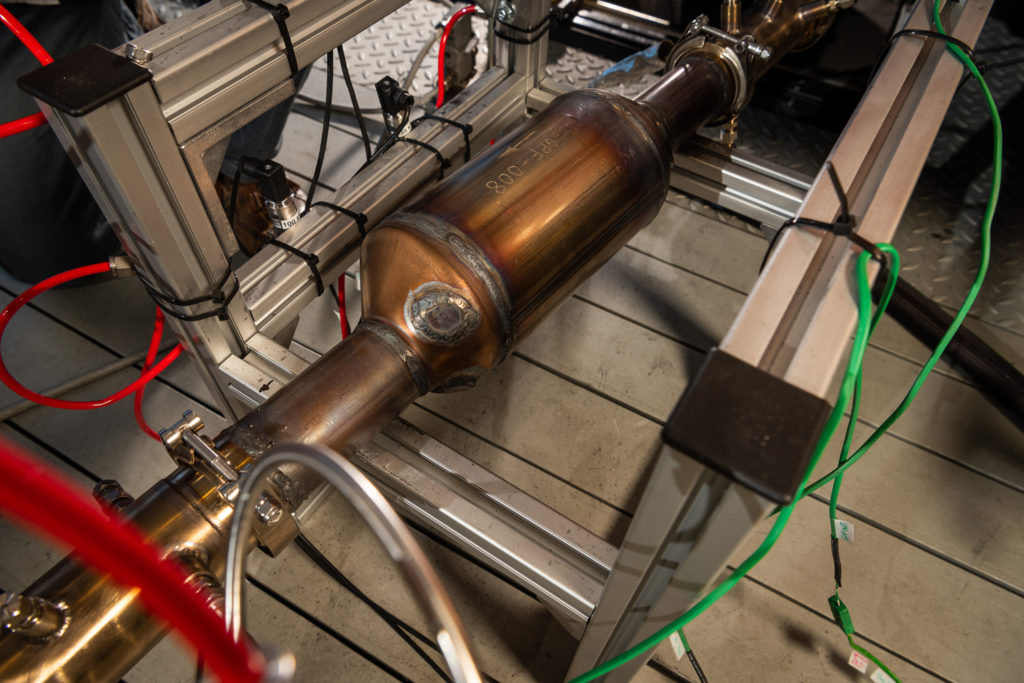

The researchers at Bath are designing a new rig capable of varying the temperature and composition of exhaust gasses entering automotive aftertreatment system components – such as GPFs, in order to identify the optimum conditions for the soot burn rate of GPFs.

A test vehicle will be put through its paces on the university’s rolling road with the bespoke rig enabling the temperature and exhaust gas composition entering the aftertreatment components to be controlled.

GPFs ensure the particulate emissions from a petrol combustion vehicle are kept to a minimum and within the latest Euro 6 standard emissions requirements. This is achieved by the GPF trapping and safely removing harmful particulates from exhaust gasses.

Particulate filters can become blocked over time requiring them to complete what is known as a regeneration cycle, where the temperature and gas composition in the engine enables the particulate filter to safely burn off particulate matter trapped in the filter.

Using this new rig, the researchers are also investigating the performance of catalyst washcoats and coatings for reducing the temperature at which harmful emissions begin to be converted into the more benign species – water, nitrogen and carbon dioxide.

In better understanding the impact of catalysts on the temperature needed for conversion to occur, the researchers hope to be able to minimize the time taken for the catalysts to become operational after the vehicle has been started and reduce vehicle emissions under real-world driving conditions.

This work will support SAIC Motor’s gasoline vehicle aftertreatment development program and feed into SAIC Motor’s global product development activities in the UK and China. SAIC Motor expects this partnership with the University of Bath will contribute to its knowledge of GPFs and catalyst formulations.