Testing specialist FEV conducts projects across the gamut of propulsion technologies and as such, is well placed to assess the benefits and disadvantages of different approaches. Here, the company outlines the case for hydrogen’s place in the energy ecosystem, as a zero-emission fuel for IC engines.

The expansion of e-mobility is seen as an important step toward achieving the set climate targets. “However, we must always consider the relevant application scenario when making technology choices,” notes Professor Stefan Pischinger, president and CEO, FEV Group. “This has prompted a significant step-up of the debate surrounding the hydrogen engine as another sustainable drive form with vast potential for numerous areas.”

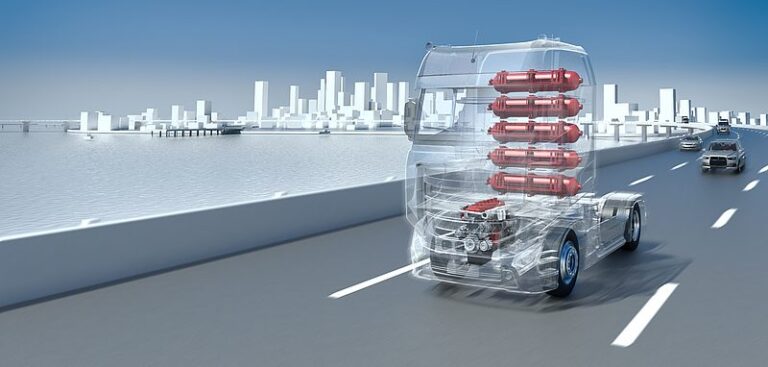

As a zero CO2 , renewable energy source, hydrogen can be transported over long distances and used to store large amounts of energy. Hydrogen use has the potential to decarbonize parts of the transportation sector where electrification through using heavy batteries is inefficient, including for commercial vehicles, buses, large passenger cars, and even trains and ships.

The infrastructure, which is expected to be in place by 2030, is reviving the debate on what would be the most appropriate way to use hydrogen. The one advantage that fuel cells have is their high degree of efficiency at low loads. But at higher specific loads, their efficiency level deteriorates in comparison with the hydrogen internal combustion engine whose degree of efficiency may be poorer at low loads but increases the higher the load. In other words, the efficiency benefits vary depending on the load.

Despite the known advantages, fuel cell development is still in its early stages, and very few development and testing methods have taken root so far. The hydrogen internal combustion engine, on the other hand, is a robust, cost-efficient option for zero-CO2 transport that can be implemented quickly under the current production infrastructure and also offers potential for existing vehicles.

The key focal areas for development of the hydrogen internal combustion engine are:

• fuel-carrying components

• ignition system

• crankcase ventilation

• direct gas injection fuel mixture system

• charging

• engine control

• exhaust gas aftertreatment

Because hydrogen is a carbon-neutral fuel, only minimal amounts of the emission components hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2 ), and soot are produced from burned lubricant. The reduction of oil consumption is thus another focus of development. The main exhaust gas component is nitrogen oxide (NOx). Thanks to its very high laminar rate of combustion and broad ignition limits, hydrogen allows for lean burning with a large amount of excess air.

Its low exhaust gas temperatures mean that – even without exhaust gas aftertreatment – the level of nitrogen oxide is already below the current limits. Aftertreatment is an effective means of further reducing the NOx emissions. Efficient lean burning also produces a consumption advantage over conventional combustion engines.