Gary Etherington – manager at temperature control solutions company Julabo – discusses the importance of thermal management in electric vehicle development.

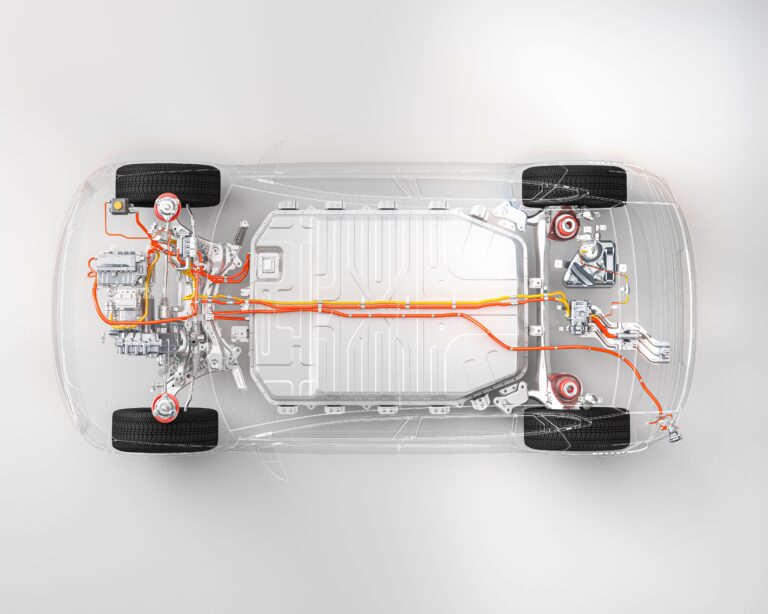

In a traditional ICE vehicle, the thermal management can be best summarized as the removal of excess heat from the combustion process. However, within fully electric or hybrid vehicles thermal management is significantly more important and therefore challenging.

Thermal control of an EV starts with the very first step, charging of the battery. There are an increasing range of power inputs to vehicles, both AC and DC, and at this point the power inverter needs to be temperature controlled. The battery itself needs to be controlled, especially during rapid charge, to prevent thermal runaway but also what is less well understood is that the efficiency, level and repeatability of the charge are all heavily influenced by the temperature of the battery during charging.

Then, during operation of the vehicle, the range and lifetime of the battery are massively influenced by the temperature. For example, at 5°C the range of EV batteries can be reduced by up to 44%. In addition to the vehicle drive mechanism there is also the need for climate control within the vehicle, all of which require temperature control components.

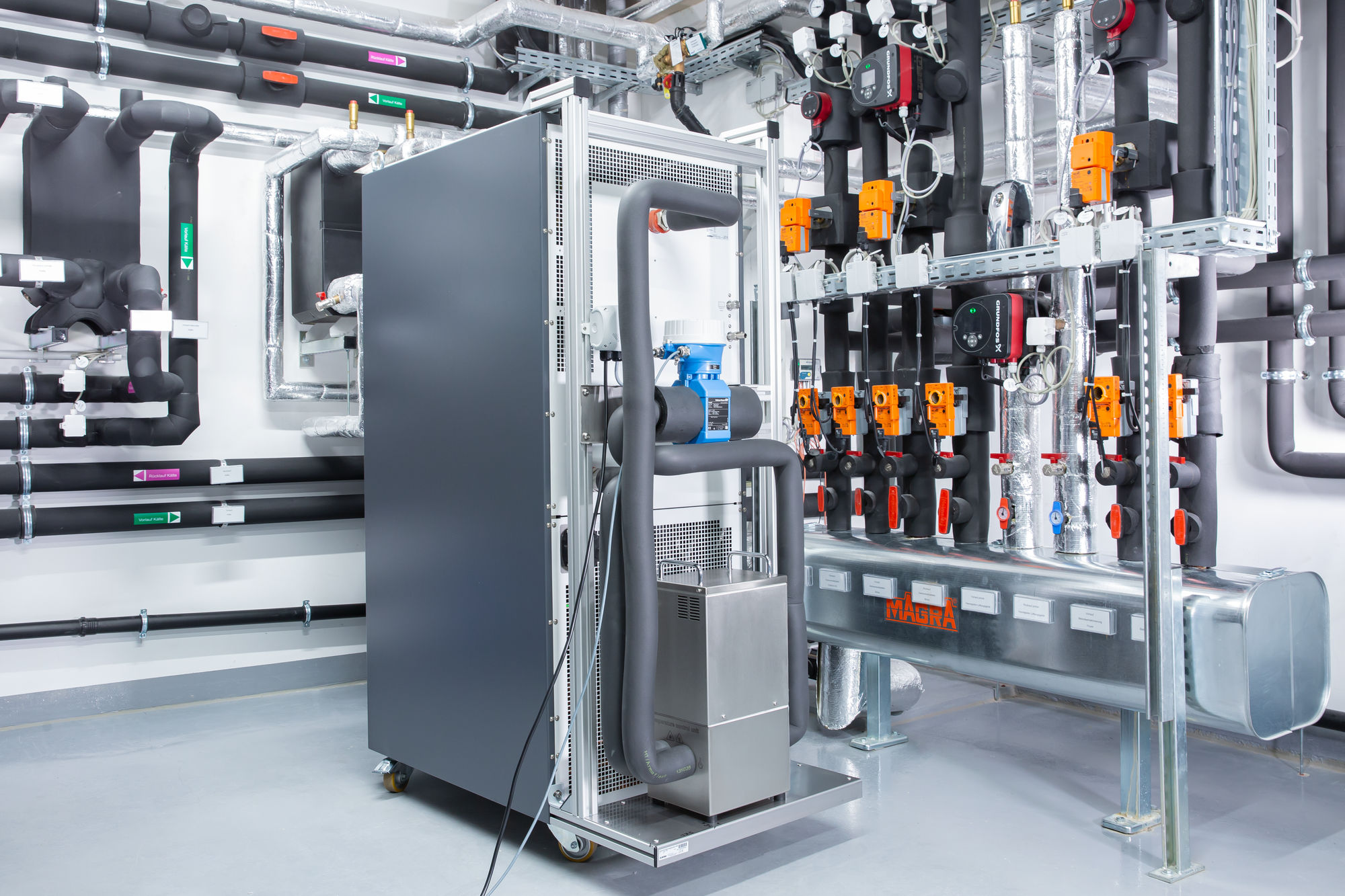

Julabo offers a comprehensive range of temperature control solutions to simulate real-world conditions so that each component can be tested, in research or in series production. This includes the precise delivery of engine coolant at both controlled temperature and controlled flow rate so that performance can be assessed and proven in extreme conditions.

The special projects division of Julabo has developed, in partnership with vehicle and component manufacturers, turnkey solutions to allow for the rapid cycling of product plus temperature profiling across the entire automotive temperature range. These includes inverters, motors, switch valves and – of course – batteries.

In addition, the company has developed solutions to allow for the measurement of charge/discharge cycles of batteries at different and changing temperatures that enable the understanding and development of lifetime figures for battery packs working under real-world conditions.