Daniel Barel, CEO at REE Automotive, believes OEMs need to rethink electric vehicle design and production to meet changing customer requirements.

Electric mobility is rapidly changing the transport landscape as we know it. As markets around the globe grapple with electricity as the source of power for transportation, OEMs and commercial vehicle manufacturers alike are working hard to provide compelling vehicles – that not only meet customer demands but also increasingly stringent carbon emissions regulations.

Some car companies and commercial vehicle manufacturers have already adapted their existing models to run on electric power, which has its challenges, but the main components are already there, the wheels the brakes, the body, the interior. The challenge is to integrate battery, motor and inverter into the existing architecture without impinging on cabin or cargo space. But the majority of these architectures are already space limited.

The problem that a lot of manufacturers face is their legacy. Customers have expectations of brands, and that constrains a brand as to what it can offer. The method of production is also an issue. The production line has been finessed over a hundred years, but most are not yet set up to build the next generation of vehicles, and the cost also to overhaul them is huge.

What manufacturers need is the assistance of a company that is already thinking three steps ahead of them. A company that already has the answers to a lot of these questions. To make an archaic analogy, currently the industry is arguing about VHS or Betamax – but what is needed is a company already working on a prototype online streaming service.

And, at REE Automotive, we’ve spent many years thinking about the ideal solution for the automotive industry, and it has three layers: An EV Platform Provider – the company that develops the EV chassis. Essentially the basis on which services and applications will be run. A Service Provider – the operator of the service (e.g. Amazon or DHL). A Data Provider – the provider that monitors communication, cloud computing and cybersecurity, helping it run smoothly and improve over time.

And, at REE Automotive, we’ve spent many years thinking about the ideal solution for the automotive industry, and it has three layers: An EV Platform Provider – the company that develops the EV chassis. Essentially the basis on which services and applications will be run. A Service Provider – the operator of the service (e.g. Amazon or DHL). A Data Provider – the provider that monitors communication, cloud computing and cybersecurity, helping it run smoothly and improve over time.

Ultimately, these layers will operate as one, to provide mission-specific vehicles tailored to customers’ exact needs and requirements.

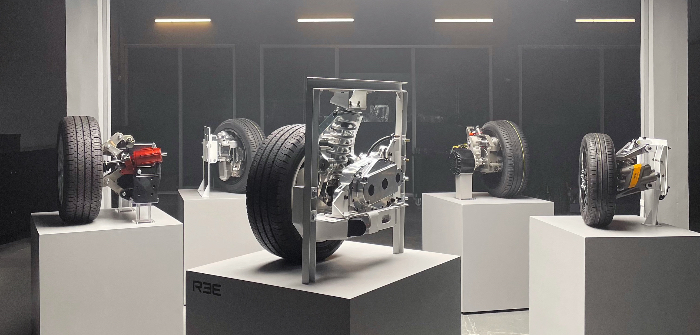

The platform provider should be able to provide an EV platform which is fully scalable, and configurable for any power or driver options. Our thinking has led us to the creation of our proprietary REEcorner technology, which packs critical vehicle components – including steering, braking, suspension, powertrain, and control – into a single compact module located between the chassis and the wheel, creating a fully flat EV platform.

Each REEcorner is a standalone system architecture based on x-by-wire technology with independent corner steering, braking and torque vectoring, which is aimed to deliver higher vehicle stability and a smoother ride. The e-motors are placed between the chassis and the wheel, so they are fully protected, eliminating the risk of high voltage cables being exposed in the event of an accident. Unlike in-wheel motor systems where motors increase unsprung mass and are prone to damage from curbs and rocks. REE Automotive EV platforms are designed with the goal of ensuring high reliability, longer vehicle life, streamlined maintenance and improved vehicle dynamics, ride and handling.

The integration of our products into manufacturer offerings – whether it is REEcorner technology or complete EV platforms – is designed to enable an OEM to achieve a faster time-to-market. And our scalable, modular-designed REEcorners and EV platforms are designed to assist manufacturers in entering new segments and services while simultaneously reducing in-house development and design costs. This, in turn, leaves the OEM to concentrate on vehicle design, functionality, connectivity and autonomy.

For vehicle manufacturers our solution is comprehensive. And through cooperation with data and service providers, the data analysis will provide unparalleled insights for route optimization, preventative maintenance, battery management, insurance and more. The better the interaction between the layers, the better the ultimate outcome will be.