OVERVIEW

Amsted Automotive design, engineer, and produce electrified and advanced propulsion systems for top OEMs and hard-charging startups.

We are experts in high efficiency mechatronic clutch designs, electrified torque management systems, advanced metal-forming, powdered metallurgy, soft magnetic composites, precision-bearing components, and engineering and manufacturing.

We build for vehicles on the edge of tomorrow’s innovations by reducing mass, extending range, improving safety, propelling performance, and maximizing drivetrain efficiencies across industries and markets.

CAPABILITIES

- Precision bearing products

- Transform products

- Powder metallurgy

- Propulsion systems

- Net formed solutions

MARKETS

- Passenger vehicles

- Commercial vehicles

- Electric mobility

- Aerospace

- Industrial and mining

LOCATIONS

With nearly 2,000 employees in offices and plants in North America, Asia, and Europe, Amsted Automotive produces more than 100 million assemblies and components annually.

SELECT TECHNOLOGY

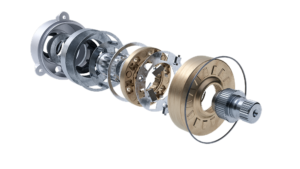

Amsted’s Dynamic Controllable Clutch (DCC) is a groundbreaking Electro-Mechanical E-axle Disconnect system that furthers efficiency and range while cutting costs for electrified vehicles.

The DCC Disconnect system effectively provides seamless engagement and disengagement of the rear electric drivetrain while maintaining on-road and off-road performance.

The DCC technology is already featured in some of the hottest EV AWD and 4WD vehicles hitting the market and the road this year.