Dontyne Systems offers software aimed at the optimum design, production, and performance of gear systems in the transmission industry. The design aspects of the software allow recognized international standards to be implemented but Dontyne also offers bespoke solutions specific to customer production including analysis of any novel designs permitted by modern CNC capability. The range of software products also integrates with machine tools and inspection equipment to allow end-to-end control of the gear manufacturing process as the company continues to help drive industry 4.0. The company has over 200 customers worldwide with much of the customer base in UK, Japan, and USA. Dontyne Gears was formed in 2013 to help our clients further by offering services such as gear design, prototyping, and testing. The investment in equipment has also enabled the development of our own products which can be sold directly to the customer to provide a more complete production solution.

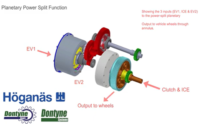

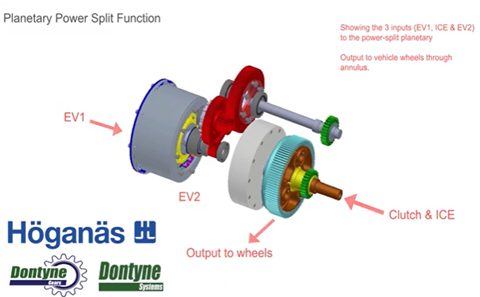

Dontyne has completed design projects for EV and ICE in automotive as well as for companies in other sectors

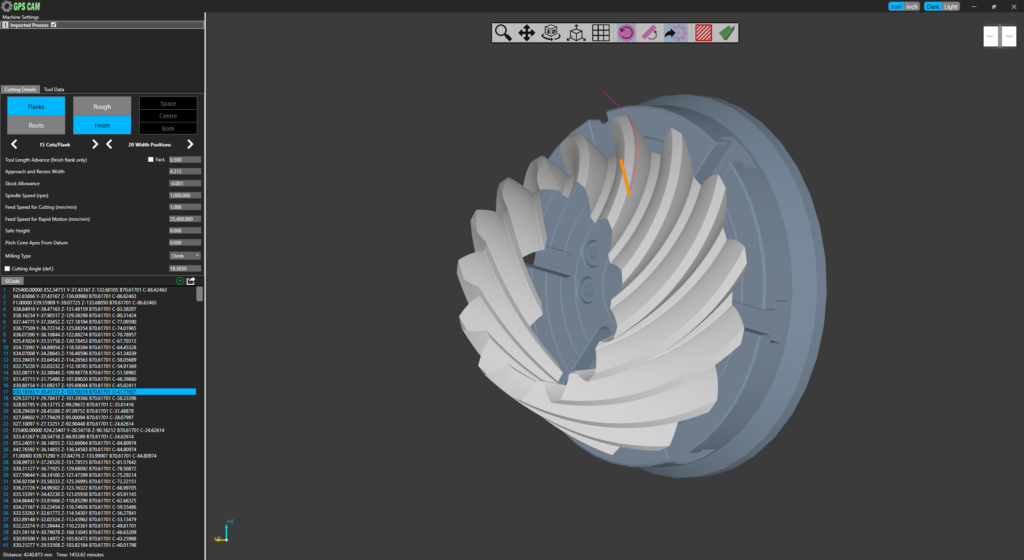

Dontyne offers manufacturing simulations for hobbing, grinding, shaping, shaving, skiving, honing, and 5-axis production

DIGGS is a Dontyne inspection solution for 100% in-line control of gear production on the shop floor using EquatorTM from Renishaw plc